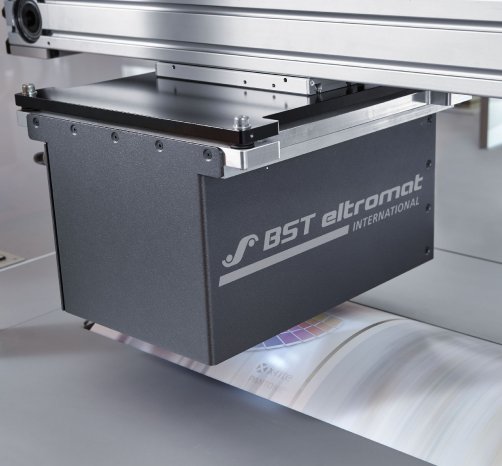

The iPQ-Center from BST eltromat is a modular system, whose individual components can be combined to create customized solutions for a host of different monitoring tasks in printing processes. The abbreviation iPQ stands for "increasing Productivity and Quality". The backbone of the iPQ-Center is the iPQ-Workflow, which integrates the three modules – iPQ-Check for 100% inspection, iPQ-View for video web inspection, and iPQ-Spectral for inline spectral color measurement – in a closed data workflow.

In flexo and gravure printing, among other applications, the X-Rite sensor specially developed for iPQ-Spectral detects the spectral color data in real time, displaying them as L*a*b* values. The machine operators get direct feedback on the quality and validity of the measurements on their control terminals. As the system promptly detects any color deviations, both in solid and half-tone colors, the machine operators can quickly eliminate their causes. The same applies to deviations in color density and dot gain. In short: this largely automated system for color management and control puts printers in a position to optimize their process and avoid or minimize paper waste. At the same time, they can provide their customers with complete color quality documentation.

Various features of iPQ-Spectral uniquely guarantee dependable color measurements. Regardless of the web speed, iPQ-Spectral reliably positions the spectral measuring head at the envisaged measuring locations, the plausibility of which can moreover be automatically verified by camera. The automatic, cyclic calibration in relation to a white normal also ensures maximum measuring accuracy. A further key element of the reliable measurements obtained with iPQ-Spectral is the backing developed by BST eltromat for use with numerous different materials. Only recently did BST eltromat and the University of Wuppertal present a jointly developed backing for transparent, incompletely opaque and other printing substrates. Here the spectral data determined on a white backing can be transformed to suit backings of any desired color with the help of an algorithm. Research results such as these are regularly incorporated into the ongoing further development of iPQ-Spectral.

Different interfaces, such as one to ESKO, provide a seamless connection between iPQ-Spectral and the prepress and print shop. For example, the production data from the pre-press is fed directly to iPQ-Spectral, this significantly simplifying and accelerating press setup, as well as ruling out input errors. This integration again contributes to printers being able to reliably and conveniently achieve the color values specified by their customers, and to dependably maintain them during production. The clearly structured presentation of the measurement results assists printers in assessing the measured colors, while they can make targeted corrections on the basis of the CIE Lab coordinates displayed.

"More than ever before, brand owners, in particular, expect their packaging producers to exploit all the available technical options in order to achieve given color values. iPQ-Spectral is the only inline spectral color measurement system working to the XRGA standard with a sensor from X-Rite, the market leader in color measurement and control solutions for printing. Thanks to our cooperation with X-Rite, we can give our customers maximum reliability in color management and control in web printing, together with the greatest possible efficiency," says Dr. Christopher Kauczor, the responsible Product Manager at BST eltromat International.

For more information, go to: www.bst-international.com and www.xrite.com