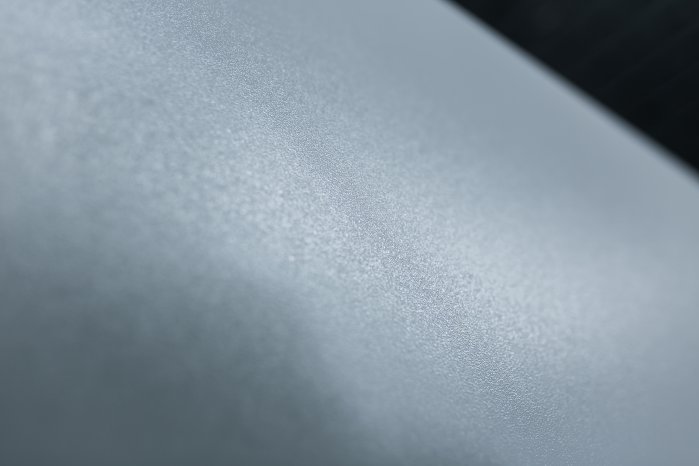

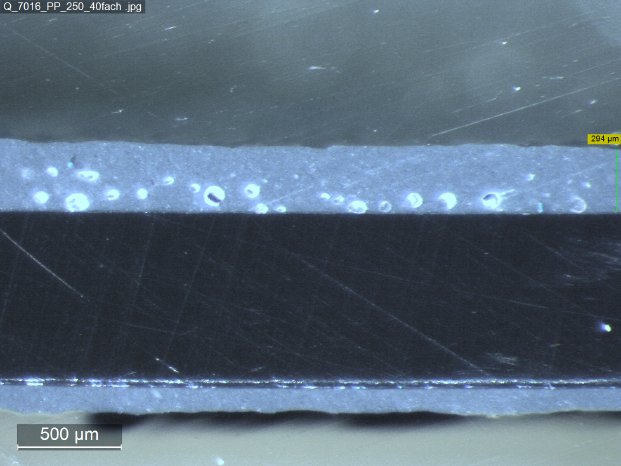

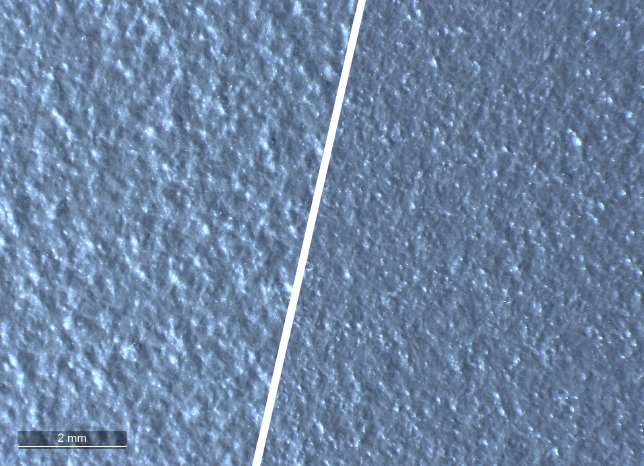

However, with the new PP5011A product range, FreiLacke has been able to successfully counter this issue: Even with layer thicknesses that are far greater than those specified in the technical data sheet, the surface will remain uniformly flat; that means the surface structure in the range between 80 and 160 μm is very homogeneous. This has allowed FreiLacke’s coating specialists to successfully provide automated coating system processors and manual coaters with significantly greater flexibility and scope when it comes to coating their components with fine-textured powder coatings.

Practical test successfully completed

The new product range for decorative, matt surfaces is suitable for both outdoor and indoor industrial uses. It scores points with its flat, fine texture, good haptic qualities and an even surface structure regardless of the layer thickness. The product also boasts good light and weather resistance. It was developed tailor-made to customer specifications within just four weeks, and has already been successfully used in practise by a manufacturer of workshop equipment. “The PP5011 A is suitable for diverse surfaces, including lights and radiators”, says coating expert Andreas Hepting.

The powder coating is based on label-free, saturated polyester resins. It is crosslinked using an hydroxyalkylamide-based curing agent. The surface structure is created using a PTFE-containing additive as well as a special additive combination that meets all pertinent requirements.

Excellent anti-abrasion and adhesive properties

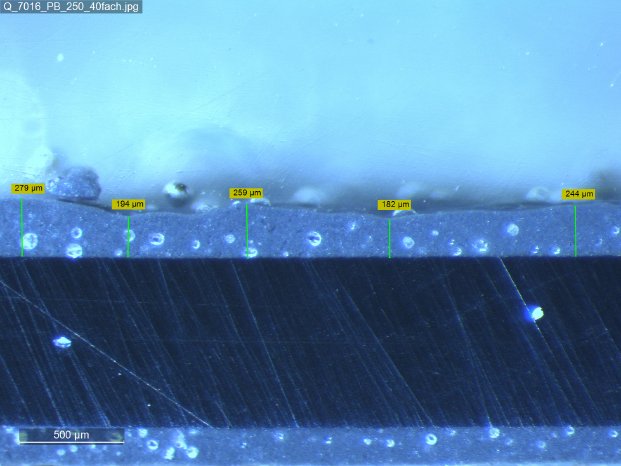

Also new to the Black Forest coating specialist's product range is the powder mix for indoor use (PB5061). In addition to its decorative, matt surface, flat texture and good haptic qualities, it also boasts excellent anti-abrasion properties. With regard to the hybrid powder coating PB5061 based on epoxy and saturated polyester resin, the surface structure is kept very even in the range between 70 and 100 µm by way of a PTFE-containing additive. Its gloss level and abrasion resistance are achieved using special curing agents and additives.

The textured powder coating also boasts outstanding adhesive properties. These qualities are highly sought after within areas such as the functional furniture segment, which requires the bonding of corresponding attachments. “Wherever there are significant mechanical influences on components, and whether these occur within the shop fittings, functional furniture or kitchen area segments, this matt coating system convinces with its excellent anti-abrasion properties”, explains Hepting. Further areas of application for the new system include the workshop equipment, storage technology and consumer goods segments.