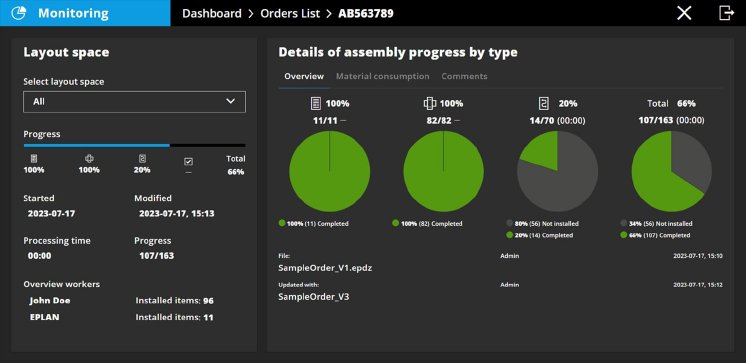

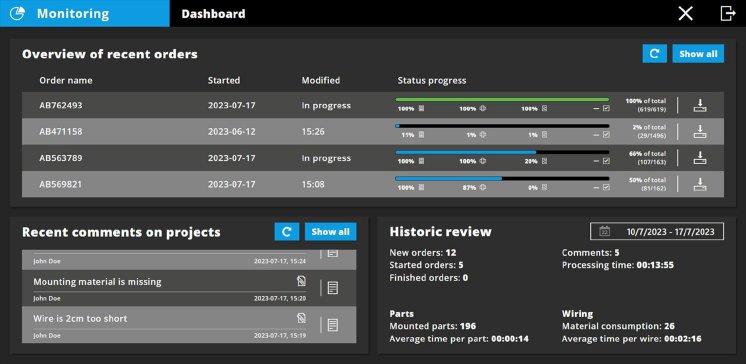

Eplan Smart Mounting makes control cabinet manufacturing and panel building even easier. It leads assembly technicians though the assembly steps for rails, cable ducts and electrical components, and shows where each component must be placed. Yet manufacturing personnel aren’t the only ones receiving ideal support; production managers also benefit from the complete overview of and within projects. This was previously just limited to a single order, but in the new Version 2024, the entire flow of orders in manufacturing is displayed. Different dashboards show all the orders currently in progress – including how far along each is in the production process. There’s a single overview where the production manager can see all the relevant information – including comments from technicians at the order level. If desired, the manager can select a (running) order and receive all the information on the progress of this individual order, thereby providing support for resource planning, improves communication amongst the team, and saving having to make time-consuming rounds on the shop floor.

Tracking for better costing

Another innovation: both Eplan Smart Mounting and Eplan Smart Wiring now simultaneously evaluate previous orders, meaning already recorded ones. The software shows how many orders have been processed during a particular time period and determines KPIs such as the average time required per component or connection. These values can ideally be used to calculate time costs for new orders, and they make it easy to test new workflows to optimise production processes. For instance, if the component labelling process is changed, the time per item can be checked after a few jobs. The detailed tracking at the work level provides an optimal overview here.

Assign components? Just scan them!

The system’s simplicity additionally ensures that companies can effectively handle the shortage of skilled employees. Even not fully skilled technicians can take on both component installation and – in combination with Eplan Smart Wiring – the cabling of a control cabinet. To make this even easier, Eplan, the solutions provider, has implemented yet another real-life innovative idea in the new Version 2024. Components can now be scanned for improved recognition. Eplan Business Owner Rapid Design Tobias Kratz explains: “With the newly integrated scan function, every component can now be clearly identified and correctly placed in the control cabinet. Similar-looking components now will not be mistaken for each other, and the workflow is also accelerated. It is therefore unambigious about where each and every device must be installed.”

Full consistency through to cabling

Technicians previously had to identify the components themselves using device numbers or with the help of a 3D macro, which definitely requires a certain level of expertise. “Now the technician simply picks up the component and a hand-held scanner, scans the EAN code, and the digital twin then shows where the component is supposed to be installed,” Kratz says. In combination with Eplan Smart Wiring, the cabling process is also supported using a uniform, system-wide foundation. Further, an interface to the Rittal Wire Terminal WT C means that the information for bundling is synchronised with the cabling list – and the cables are displayed exactly in the output sequence by the fully automatic wire processing machine. All data from engineering and manufacturing can be synchronised – based on the digital twin in Eplan Pro Panel.

Individually customisable user interface

Everyone usually prefers to work with an interface that is familiar to them, or follow an accustomed workflow. The smart systems from Eplan support this, too. For example, ERP numbers can be displayed and search and/or filtering criteria can be individually customised, as can the display of the 3D model. Either the production manager or the individual user can decided what works best. This allows applications to be ideally customised to internal processes and personal preferences can also be taken into account. This means that everyone is working in a highly efficient manner with their own optimal user interface, all adapted to the company’s production landscape.

Find out more at:

www.eplan-software.com/eplan-smart-mounting