Tens of thousands of new grid stations must be built every year in Germany alone due to the expansion of renewable energies. Both decentralisation and the significantly higher amounts of energy required in the future will necessitate a significant expansion of distribution and transmission grids. In addition, thousands of stations and substations will have to be built or upgraded. The entire energy sector is facing a herculean task that can only be mastered with standardisation, industrialisation and automation.

Focus on grid infrastructure

At the eWorld in Essen, Eplan and Rittal are presenting themselves as partners for the energy transition, whereby their motto is “Learning from Industry.” In Essen, both Friedhelm Loh Group companies are primarily focusing on the rapid and industrialised expansion of grid infrastructure, which is crucial for transforming today’s energy systems. A second focus is on the topic of decentralised energy systems: renewable energies, charging infrastructure and energy storage. If the hardware components required for this are already available with modular, industrially manufactured system technology, this infrastructure can also be rolled out quickly across the board.

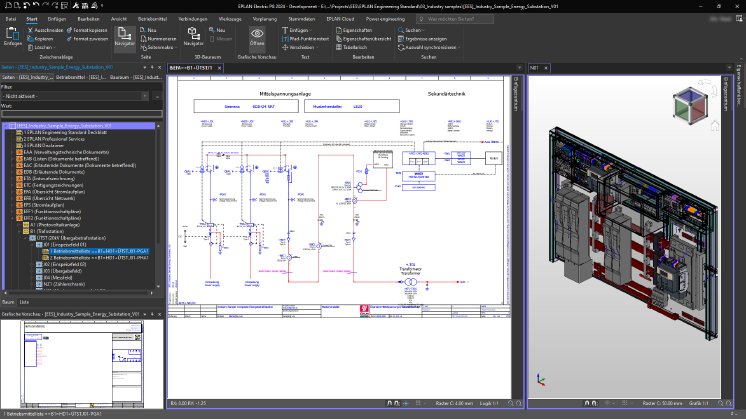

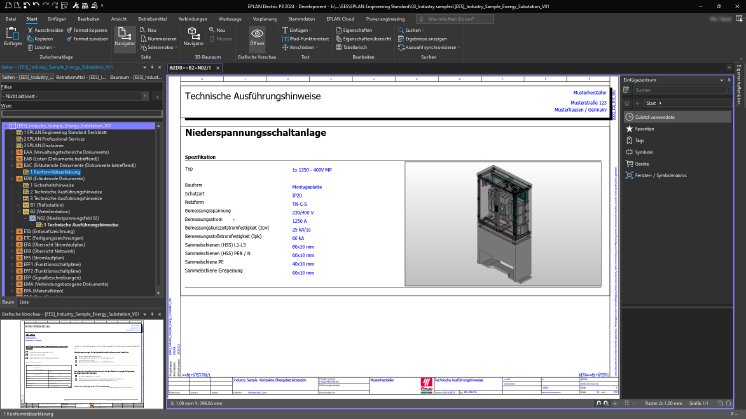

Energy transition – transformer station exhibit

The exhibit of a compact transformer station with pre-planned project documentation in Essen makes clear how the implementation can be realised. The engineering of the transformer station with a medium and low-voltage system, available as a standardised industrial project in the Eplan Cloud, will also be presented here. In practice, this example project can be used to plan grid stations, but it also shows how completely decentralised energy systems can be developed in a standardised way. From its planning and construction to the operation of the system, all aspects that play a role in the energy sector are taken into account. Furthermore, the data can be transferred 1:1 to production.

Production also included

Based on the “Copper” module in Eplan Pro Panel, copper rails (as an example), which are often used in the medium and low-voltage systems, can easily be planned and transferred directly to production. There is also data consistency with the RiPanel Processing Center. The Eplan Pro Panel software allows for efficient production management with a variety of machines from Rittal Automation Systems – including Perforex Laser or Milling systems, the Rittal Wire Terminal WT C for wire processing, or copper punching and bending machines from affiliate company Ehrt. Since the middle of last year, Rittal has also been offering the option of outsourcing the packaging and pre-assembly of power distribution systems at the Rittal Application Center in Gera, Germany. Companies benefit from the years of experience and efficiency that the Center has to offer in this field.

The digital twin makes it possible

The one thing that substations, transformers and charging infrastructure has in common is that their digital twins can be worked virtually long before any of them is built in the real world. Once they’re up and running, the digital twin will further make it possible to train for and plan service and maintenance processes without having to be on site with the equipment, saving enormous amounts of time. The experts from Eplan are working closely with other software companies and grid operators to be able to create a complete digital twin of a substation for instance – its primary and secondary technology – for grid operators.

The water and wastewater industries will also be addressed at the eWorld Energy & Water. An Eplan and Rittal exhibit will show how the ecosystems of the energy sector can work together in a consistent and integrated way with the well-coordinated solutions of software and hardware, making things faster and more efficient overall.

Find out more at:

www.eplan-software.com

www.rittal.com