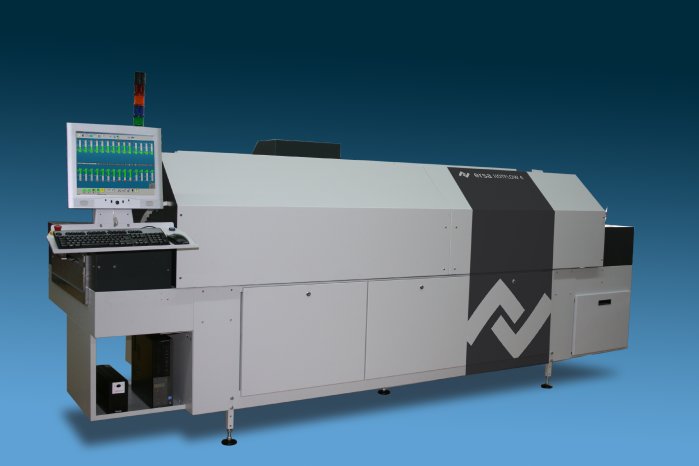

The new HOTFLOW 4 series of systems has been augmented by the Ersa HOTFLOW 4/26. This system, with a process length of more than 5 meters split into 26 heating zones and 4 cooling zones and characterized by its high energy efficiency, provides a vastly increased throughput while maintaining the customary high process- and soldering quality.

The reduction of operating cost is based on the use of economical and efficient fan motors, which reduce the consumption of power, and on the superior control of the N₂ system, which reduces the consumption of N₂ by 20%. All in all, total energy saving is in the range of 25%.

Also on display is the HOTFLOW 4/08, the shortest reflow system in the series, which provides the same technical features and therefore offers the same reduction in operating costs.

The proven reflow systems of the HOTFLOW 3/14 and HOTFLOW 3/20 series are, on account of their intelligent control systems and because of their low consumption of consumables, known and trusted as excellent all-rounders.

As the world market leader in the selective soldering technology, Ersa shows the new ECOSELECT 4. This stand-alone system, developed for mid-sized production volumes, can either be manually loaded / unloaded or by transfer to a following system. Flexibility has been designed into the unit, so that the ECOSELECT 4 can be retrofitted at a later date with additional soldering modules.

For users with larger batch sizes, the ECOCELL featuring a dip module and multi-nozzles is shown. Equipped with two solder bath, this unit supports "on the fly" product changes.

High throughput at maximum flexibility is ensured by the VERSAFLOW 3/45, which can be specified with up to 6 mini waves. Whether it is lead-free or leaded solder in mixed operations, or high throughput using different nozzles, the VERSAFLOW series is sufficiently flexible to satisfy all requirements.

The ECOSELECT 1 from Ersa is the system suitable for processing prototypes or small batch sizes. Equipped with the same components as the VERSAFLOW systems, programs written for this system can be transferred to other selective soldering units.

The POWERFLOW N₂ wave soldering system with a conveyor speed of up to 2,5 m/min is now being complemented by the PPOWERFLOW e N₂ for medium production quantities. Both systems are full tunnel units and operate under nitrogen atmospheres.

The automatic rework system HR 600 autonomously performs SMD repairs and impresses by its outstanding price / performance ratio. The system is shown with the newest software HRSoft 1.2.7. Worth to note is the route Ersa has taken in the repair of QFN's: With the Dip&Print Station, solder paste is printed onto the component prior to installation. The Dip&Print Station is available for all Ersa Rework Systems. Ersa will demonstrate QFN rework life at is booth.

The ERSASCOPE will be shown with new features: a new, energy saving LED light source provides brighter and more uniform illumination of the solder joint. Also, the newest version of the inspection software ImageDoc will be shown. To detect and document hidden solder defects the user has now the choice between Ersa MOBILE SCOPE, ERSASCOPE 1 and ERSASCOPE 2.

The range of Ersa soldering tools has also grown: with i-Con Vario 2 and i-CON VARIO 4 Ersa presents two high-performance multi-channel soldering and desoldering stations.

A hot air channel with the 200 W powered i-Tool AIR S, as well as 1 resp. 3 additional tool channels which can be operated simultaneously, offer to its user a high degree of flexibility during rework, or producing prototypes and high-quality assemblies.

The extensive range of services of these two new stations as well as practical applications of i-Tool AIR S, i-Tool, Chip Tool VARIO and X-Tool are demonstrated at the booth of Ersa (A4.171), but also as part of the "IPC Hand Soldering Competition" at the booth of the IPC HSC (A3.318).