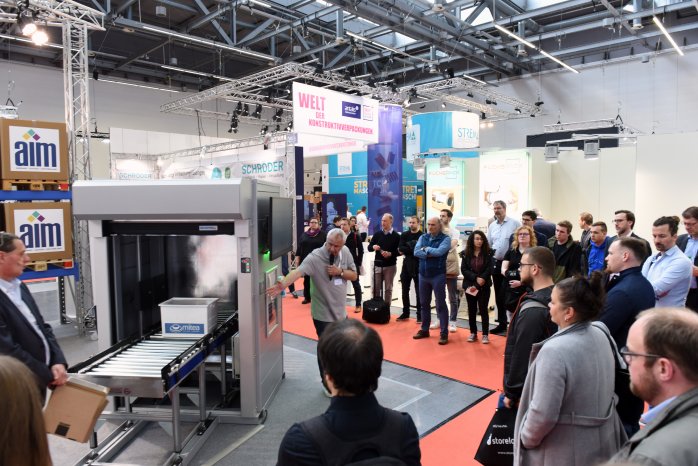

The independent jury of scholars and journalists reviewed over 100 submissions and chose three winners that fully live up to the name of BEST PRODUCT as outstanding manifestations of the award criteria: They enhance productivity, reduce costs, and streamline operations. The award-winning companies, through their products, are helping to make processes more stable yet flexible in adapting to changes. By improving efficiency, they are ultimately boosting the productivity of the logistics industry. The BEST PRODUCT award was presented in the LogiMAT Arena during the gala opening ceremony on the first morning of the trade show. Presenting the awards was Dr.-Ing. Johannes Fottner, Professor and Chair of the Institute for Materials Handling, Material Flow, Logistics at the Technical University of Munich.

In the category of “Order Picking, Conveying, Lifting, and Storing Technology,” the prize went to MEYSENS GmbH (East Entrance, Booth EO91A, “Innovation Made in Germany” joint booth) for its 3D ultrasonic sensor Toposens ECHO ONE®.

The 3D ultrasonic sensor ECHO ONE® makes it possible for mobile robots such as AGVs and AMRs to avoid collisions with all kinds of obstacles. Unlike existing sensor technologies that can be obstructed by light conditions or humidity, the ECHO ONE® uses the principle of echolocation familiar from bats to generate robust 3D location data in real time—irrespective of the on-site conditions. “The 3D ultrasonic sensor Toposens ECHO ONE® is the virtual eye of autonomous systems, complementing camera-based image recognition with the safety-enhancing feature of reliable object recognition,” remarks Prof. Fottner, a member of the jury, speaking during the award presentation.

Conventional sensor systems are typically based on optical technology, compromising their ability to detect objects when the optical environment is not ideal and leading to avoidable collisions. An acoustic sensor like ECHO ONE® uses fundamentally different sensor technology. It can help with 3D multi-object detection of complex or transparent objects in the ultra-close range of 10 cm up to 3 m, plus a wide-angle field of view of up to 160° in the ultra-close range and up to 110° at 3 m. This is particularly important for detecting forklift forks, which are among the more complex objects for sensor-based object detection and carry a potential for danger if not properly detected—especially in intralogistics and above all in mixed intralogistical operations.

“What's impressive is that it can reliably detect complex objects, even glass and other materials that are challenging in optical processes. This gives the sensor a key role to play in the safe operation of modern autonomous 3D systems,” adds Prof. Fottner.

The sensor compensates for the shortcomings of optical sensors, which can have problems detecting glass or reflective surfaces, by using sound-based triangulation in combination with sophisticated noise-filtering software. This delivers robust 3D data output in real time for each obstacle detected within the fully configurable, dynamic warning and stopping zones. The system offers digital inputs and outputs plus ethernet as a hardware interface. Detecting even the most complex objects in its surroundings with a small blind zone cuts down on costly accidents while ensuring the utmost safety in any environment. This makes ECHO ONE® the ideal solution for the safe and reliable navigation of mobile robots in intralogistics.

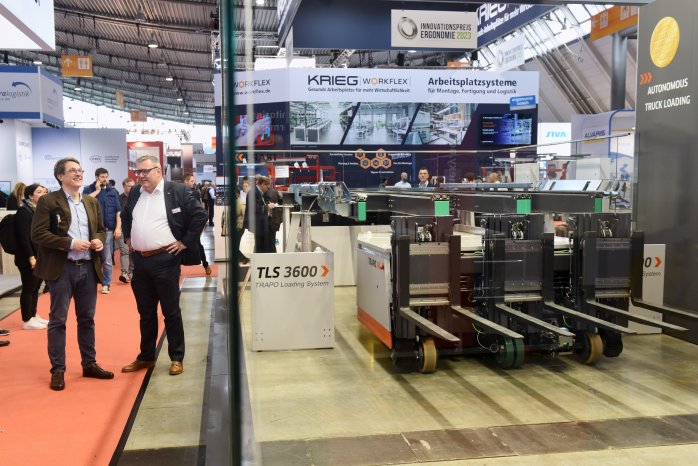

In the category of “Identification, Cargo Securement, and Packaging and Loading Technology,” the award went to TRAPO GmbH (Hall 5, Booth 5D53) for its TLS 3600 loading and unloading system, which autonomously transfers pallets between warehouse and truck.

The TLS 3600 closes the safety gap in loading zones. Used in tandem with AGV systems, it can replace the usual forklift transport of palletized goods between production, storage, and loading zones with a fully automated process, protecting people and goods alike during loading and unloading.

The TLS 3600 is whisper-quiet in the loading zone, replacing the usual hustle and bustle of forklift traffic. The arriving truck driver uses a control panel screen in the waiting zone to log in, triggering the automated loading or unloading process. The TLS 3600 handles the process safely and autonomously using optimized routes. It can even run 24/7 as part of an effective overall logistics strategy.

“We’ve been trying for decades to shorten the idle time of trucks at the loading dock. TRAPO offers a better overall solution for box trucks, and without any special installed equipment. The system can even tolerate small discrepancies in the alignment of the truck,” remarks Prof. Wolf Michael Scheid, a retired department head and member of the jury.

The TLS 3600 takes its name from a unique feature: It can load three pallets of 1,200 kg each (= 3,600 kg) in a single run.

The pallets are staged using either conventional technology, a shuttle swarm, or an XXL shuttle—the latter delivering three pallets at a time. Loading is a three-step process: First, up to three pallets are placed side by side in a row on the conveyor (step 1) and aligned. The row of pallets is then picked up (step 2) and loaded (step 3). While one row of pallets is loaded, the next row is staged—a continuous process that saves time and optimizes movements.

Competitors mainly offer one-shot systems, staging the entire truckload in the loading zone before loading it all at once. The main problem with this is that it unnecessarily blocks a huge staging area some 20 meters long in the already tight space.

The TLS 3600 is flexible and integrates optimally into the warehouse logistics. It can be operated autonomously as a rigid system or moved between loading bays. It uses rear-wheel steering to automatically correct its position on the loading dock when entering the truck.

In the category of “Software, Communications, IT,” the award went to Greenplan GmbH (Hall 8, Booth 8A71) for its Greenplan route planning algorithm.

Greenplan offers cloud-based software solutions for planning dynamic routes that are both efficient and sustainable. Route planning is based on a mathematical algorithm that can boost efficiency by up to 20%.

Two other special features are dynamic planning and the concept of overlapping districts. Fully dynamic routing eliminates fixed delivery districts, optimizing all delivery zones and better balancing volumes across all delivery runs. Travel times are also optimized, yielding cost efficiencies. Daily routes vary, since they’re based on actual shipping volumes, not averages. This makes it possible to slash the number of runs: One European postal carrier was able to lower its planning requirements from 63 vehicles a week to 32. Ultimately, this results in lower CO2 emissions, of course. Overlapping districts offer a compromise between fully dynamic routes and fixed delivery districts. They eliminate the unbalanced routes that result from zones based on postal codes, for example. They overlap at their borders by a few kilometers so that drivers can also drive to addresses close to their actual destinations and specifically plan in nearby parking locations, for example.

“The software optimizes routes using an algorithm developed in partnership with the University of Bonn. Routes are planned dynamically based on actual shipping quantities. This can reduce the number of runs, resulting in lower CO2 emissions,” notes Dr. Robert Schulz, a juror and Professor at the Institute of Materials Handling and Logistics at the University of Stuttgart. “Viewing historical speed profiles of individual road segments based on time of day also allows for better planning of routes and runs.”

Another challenge in route planning is that despite the promise of optimized planning, most route planners produce inefficiencies and problems because they don’t take into account actual traffic conditions. Greenplan, on the other hand, works with historical speed profiles, which yield information about average speeds at a given time on a given section of road. The result is travel times that are dependent on the time of day, making it possible to optimize the planning of stops and adhere to target time slots. Since travel times on the same road vary significantly throughout the day, this naturally affects how stops are planned. The algorithm identifies the optimal routes from real, road-specific traffic flow speeds, recognizing when it really makes sense to route a vehicle onto a main road, for example. This avoids traffic jams, helps drivers spend less time in traffic, and avoids adding to congestion in city centers.

The three products awarded BEST PRODUCT 2023 are representative of the many exhibitors from around the world presenting their innovations to industry professionals at LogiMAT. The International Trade Show for Intralogistics Solutions and Process Management, the largest of its kind worldwide, continues through April 27, 2023, at the Messe Stuttgart convention center.

Organized by: EUROEXPO Messe- und Kongress-GmbH

Joseph-Dollinger-Bogen 7 | 80807 Munich, Germany

Phone: +49 89 32 391 259 | Fax: +49 89 32 391 246

www.logimat-messe.de | www.logimat.digital

Background information:

The BEST PRODUCT award was initiated by the organizers of LogiMAT in order to draw attention to the outstanding achievements of the exhibitors, many of whom are small or medium-sized businesses. Over the years, the award has honored innovative products that have made a significant contribution to streamlining processes, cutting costs, and enhancing productivity in the internal logistics of businesses. The BEST PRODUCT award is presented in three categories:

- Software, Communications, IT

- Order Picking, Conveying, Lifting, and Storing Technology

- Identification, Cargo Securement, and Packaging and Loading Technology

Members of the BEST PRODUCT award jury:

Prof. Johannes Fottner (Dr.-Ing.), Chair of the Institute for Materials Handling, Material Flow, Logistics at the Technical University of Munich (Jury President)

Prof. Rolf Jansen (Dr.-Ing.), Institute for Distribution and Retail Logistics (IDH) at the Society for the Promotion of Innovation in Logistics (VVL e.V.)

Jan Kaulfuhs-Berger from the industry journal Technische Logistik

Matthias Pieringer from the industry journal LOGISTIK HEUTE

Prof. Wolf-Michael Scheid (Dr.-Ing.), Association of German Engineers, Society for Production and Logistics (VDI-GPL)

Prof. Robert Schulz (Dr.-Ing.), University of Stuttgart, Institute of Mechanical Handling and Logistics (IFT)

Tobias Schweikl from the industry journal LOGISTRA