Therefore a non-contact and non-destructive inspection immediately after the adhesive application is possible. Thanks to the inspection with a laser sensor, the system is not effected by reflexions of the "wet" glue or incidence of extraneous light. So it is also possible to measure e.g. a white adhesive bead on a white background.

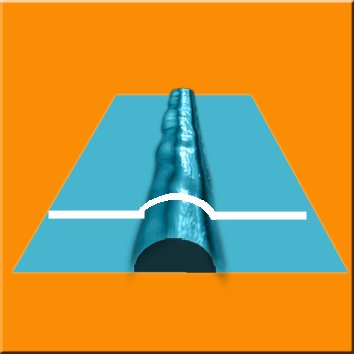

EyeSens AdBead is suitable for the recognition of disruptions, slubs and contractions on adhesive beads - for all glues and surfaces as well as for recognition of asymmetries and local defects of adhesive beads.

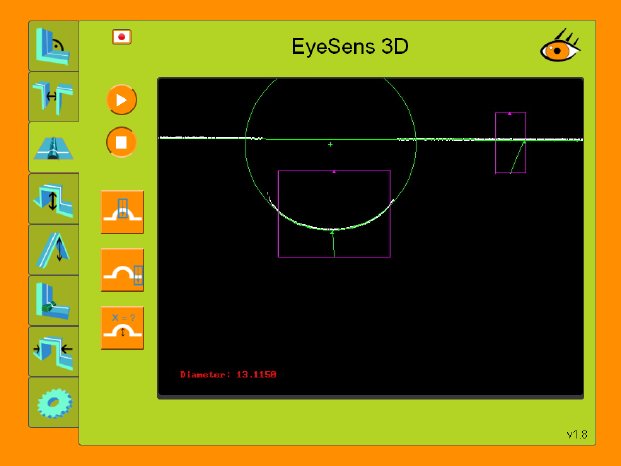

EyeSens AdBead is measuring the surface profile of the glue. And thanks to the EyeSens 3D software it is defined automatically if a bead is too narrow, too wide or too flat.

The measuring procedure is based on the principle of the laser line scan method. While the laser line is projected onto the bead, the sideways mounted camera is capturing the elevation profile of the object. Therefore a three-dimensional image of the adhesive bead is created step by step.

The EyeSens AdBead system has available the EyeSens webinterface. It is therefore not only possible to control the complete inspection program, but also to configure the program with prefabricated commands on a completely new object.

To do this, no special software has to be installed on the computer. The user only has to type the IP address of the camera into the browser and the EyeSens AdBead programming surface appears. Due to the icons the handling of the AdBead web interface is self-explanatory and allows an intuitive operation. No programming skills are necessary.