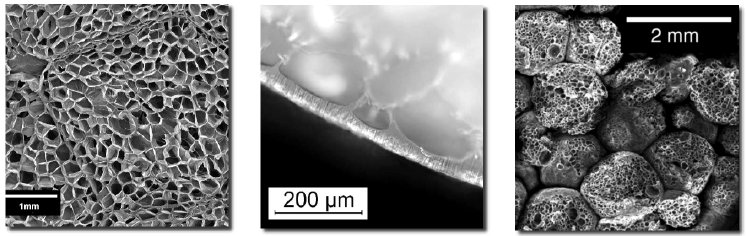

With the SLENTITE® insulation panel, BASF Polyurethanes GmbH, under the leadership of Dr. Marc Fricke, has developed a high performance insulation material with a unique combination of material properties. For the first time it was possible to produce a purely organic aerogel, on the basis of polyurethane, as a mechanically stable panel that convincingly unifies several exceptional properties. With its very low thermal conductivity and open pore structure SLENTITE® achieves an unprecedented insulation performance, which allows a 25 to 50 percent slimmer and thus space saving insulation as compared with conventional materials. The special open pore structure also has a moisture-regulating effect, which ensures a favourable climate indoors. The product is currently in the pilot phase and the first panels are undergoing practical tests by select partners.

Development engineer Oskar Schmidt submitted the cellulose foam CELLUFOAM in the category ‘Technology’ for the Swedish company Cellutech AB from Stockholm. CELLUFOAM is not only an environmentally friendly cellulose foam but actually has a natural origin. This multifunctional foam is obtained from Scandinavian wood and produced in a solvent-free process, which means this high performance product is fully regenerative and biodegradable. A highly interesting and versatile material consisting of nanocellulose and with very good mechanical and chemical properties. CELLUFOAM can not only be used for acoustic and thermal insulation but also for liquid absorption or as packaging material. The nature of this sustainable product can be tailored to the required application, opening up virtually unlimited possibilities for use in a wide range of industries. One attractive application example for the innovative material is the Cellutech Helmet, created in collaboration with the Swedish designer Rasmus Malbert – a cycling helmet made completely out of wood.

An all-rounder specifically in the sector mattress production is the foam xdura® which was also chosen for an award by the FSK team of experts. Eurofoam Deutschland GmbH Schaumstoffe from Wiesbaden introduced this universal product to the market in spring 2016. With xdura®, in contrast to the well-known foam categories in the bedding sector aimed at different functions, Eurofoam aspires to unite the various requirements placed on a modern day mattress foam. Even long term use and nocturnal sweating will not affect the form of this durable foam and yet at the same time the material is elastic and particularly tear resistant. The open pore cell structure offers maximum comfort thanks to the supple surface and inner stability and also prevents the accumulation of heat and moisture. The innovative “one fits all” foam with the perfect micro climate is already being used for first mattress cores.

The latest development of ISL Schaumstoff-Technik GmbH from Viernheim focuses on sustainability and the reduction of storage and transportation costs. Since the middle of the year, the company has been producing innovative folding containers made of expanded polypropylene (EPP). The new ISL folding container was developed in a remarkably short development phase of only twelve weeks. Stability and load-bearing capacity of the containers ensure perfect storage as well as safe transport, even of bulky and heavy goods. A clear advantage is the cost-effective production since, as a rule, no additional tool costs are incurred. The new boxes can be used flexibly, as they can be produced in almost all sizes and their "folding height" can be individually selected by each customer. Another advantage is that each EPP container can also be retrofitted to a stable folding container.

Master graduate Georg Tauer received the award for young talents in the category ‘Technology’ by proposal of Prof. Dr.-Ing. Volker Altstädt from the Polymer Engineering Institute of the University of Bayreuth. In his master thesis, the successful graduate studied the production of particle foams with variable skin thicknesses. The objective was to develop a method for the targeted modification of particle foam thicknesses in order to gain a basic understanding of their effect on mechanical properties. Georg Tauer developed a method for the reproducible production of EPS particles with a homogeneous foam layer thickened by a factor of 25. Even though particle foams have been on the market for a long time, their complex internal structures are still largely unexplored. The findings gained by Mr. Tauer's work open up an exciting range of optimization and application possibilities.

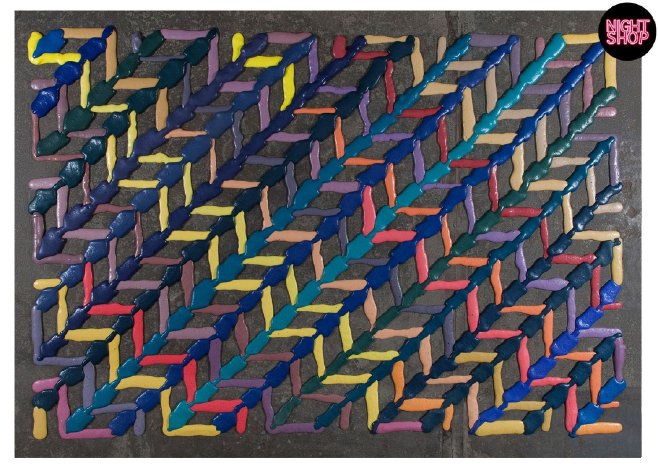

In the category ‘Design and Construction’, the FSK presented a company and a young talents award for an outstanding art project. The Rotterdam design agency NIGHTSHOP created large-format wall carpets - so-called Showdown Carpets - using a two-component soft polyurethane foam. Inspired by commercial anti-slip mats, Adriaan van der Ploeg and Ward van Gemert developed the idea of experimenting with this soft and grippy material and creating effectual art objects. Ten unique, handmade carpets were created by combining differently coloured polyurethane foams. PU components were mixed in large disposable syringes and quickly applied to the substrate via prefabricated templates. The result is powerful plastic patterns, reminiscent of colourful West African ornamentation. These works of art are currently on display in Rotterdam at art galleries and in furniture stores.

Polyurethane foam carpets by the Rotterdam Design-Studio Ontwerpbureau NIGHTSHOP.

Product and accessory designer Teresa Mendler, who is currently working on her diploma thesis at the Academy of Art & Design in Offenbach, also impressed the audience with her Office Pieces. By using PUR foam in combination with fabric, she developed a collection of two and three-dimensional spatial objects, which can be used as room dividers or artistic acoustic elements in large rooms. The aesthetics of the objects, each acting differently depending on positioning, evolved from the intense examination of the materials used and their properties. In the future, Teresa Mendler plans to create similar design objects for outdoor areas as well.

For further information please contact FSK under www.fsk-vsv.de or

Tel.: 0711 993 751 0

File copy requested.

![office_pieces_02[1].jpg](https://cdn.pressebox.de/r/ec796d6f3b5fdd1b/attachments/86/72/93/thumbnail_867293_746x466.jpg)