Designed for prototyping and high-yield production duties, the system supports all bonding technologies specifically required for the assembly of e.g. Silicon Photonics and photonic/ optoelectronic components in the field of data and telecommunications, high power lasers and other industrial semiconductors, as well as 3D sensors/ LiDAR for augmented reality, automotive applications and many more.

Depending on specific needs, the modular FINEPLACER® femtoblu can be individually configured and upgraded in-field to support additional applications and technologies.

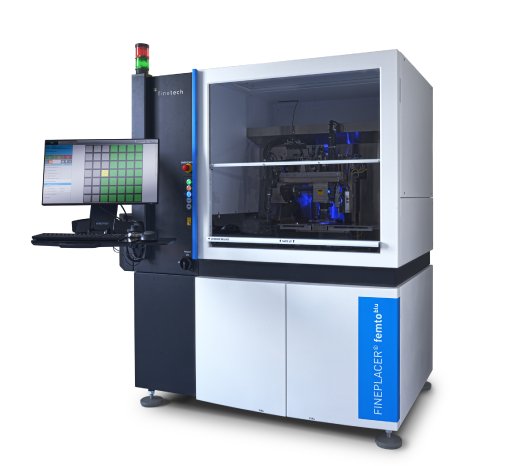

A complete machine enclosure with optional HEPA filter minimizes external influences to ensure a stable process environment and protects the operator against gas, vapor and UV radiation.

The “DualCam” visual alignment system provides application-specific fields of view, digital zoom, and delivers optics shifting along the X-axis for optimal viewing of a wide spectrum of component sizes. The dual camera module ensures very high angular accuracy during alignment and almost completely eliminates coupling losses due to twisted components. Various LED lighting options ensure optimum contrast ratios at all times and support highly stable processes.

Process optimization with software power

IPM Command, the advanced FINEPLACER® operating software, supports a consistent, ergonomic and clearly structured process development. It enables the synchronized control of all process parameters and additional process modules and provides pattern recognition for the automated alignment of substrates and components based on their structures and patterns.

IPM Command offers an unparalleled range and depth of user intervention options for process control and optimization. This allows sophisticated alignment and assembly processes of the highest quality.

Seamless transition from R&D to production

The FINEPLACER® femtoblu follows Finetech's "Prototype to Production" approach of a hardware and software platform that is consistent across FINEPLACER® machines of the new generation. It enables R&D processes to be seamlessly transferred in all their technological diversity from the development lab to the production environment. This opens up adapted product development strategies with minimized financial risk, especially for users with small and uncertain development projects.

They start their development projects with a comparatively low initial investment on a manual FINEPLACER® R&D bonder. In the creative phase, they benefit from the open design and all the freedom of a versatile and highly adaptable development system. Once the new product is ready for production, the R&D processes are transferred to a FINEPLACER® production system and automated without additional development effort. For example, this can be the FINEPLACER® femtoblu, which enables product developers to cost-effectively enter the fully automated production of innovative photonics products.

Learn more about the FINEPLACER® femtoblu at CIOE 2021, booth #14C61-1, and at Productronica 2021, hall B2, booth #411.