The expansion of electro-mobility requires electric cars to have longer ranges. Lightweight materials with optimized material properties can help put this into practice. The key to this lies in the combination of ultra-high-strength aluminium alloys and new forming processes so that local component properties can be adjusted as required. In order to make optimum use of the lightweight construction potential of aluminium alloys, the geometric and microstructural complexity of products must be increased.

Structural durability plays a central role here. Previous evaluation concepts, however, can only reproduce local material properties to a limited extent due to the manufacturing process. The Fraunhofer LBF is developing new evaluation concepts for process-related structural durability within the framework of the central LOEWE project, ALLEGRO, taking into account the cyclical transient material behavior, in order to be able to increase the lightweight construction potential of the new manufacturing processes. »With these more precise assessments, improvements can be achieved in the fatigue life approach of components according to the material. They are an important prerequisite for the industrial application of the new technologies and enable a more sustainable product design in lightweight construction,« explains Maciolek, a researcher at Fraunhofer LBF.

Materials examined down to the smallest detail

As part of ALLEGRO, the Darmstadt-based scientists are specifically trying to use process-related properties of ultra-high-strength aluminium alloys to improve the service life of components. For this purpose, the Institute for Production Technology and Forming Machines at the Technical University of Darmstadt and the Department for Separating and Joining Manufacturing Processes at the University of Kassel are developing manufacturing technologies as part of LOEWE's ALLEGRO project in order to implement both ecologically and economically efficient forming processes with integrated heat treatment. In future, these processes will be used to produce semi-finished products with locally adapted properties that have been calibrated to suit the function and loads of the application in question.

The scientists at Fraunhofer LBF are investigating the entire process chain in order to be able to take advantage of the local process-related properties in terms of lightweight construction using the example of an e-bike frame. The microstructure and the material properties are influenced by various process steps along this chain, which in turn determine the component behavior. If these local material properties can be determined and taken into account in the design and evaluation of cyclically stressed components and structures, then the potential in lightweight construction can be exploited in a targeted manner.

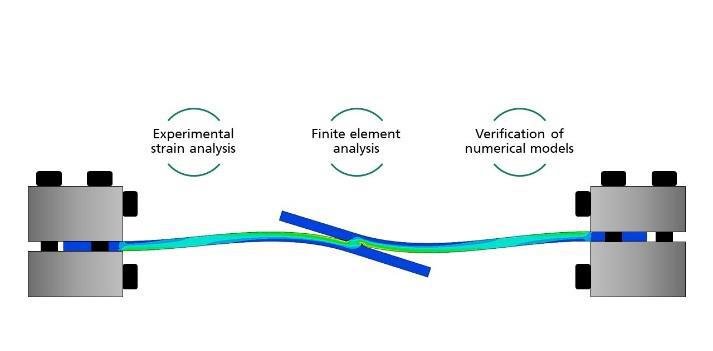

Since components are usually composed of several semi-finished products, the scientists must also investigate the joinability of the graded semi-finished products. The challenge when it comes to joining is to maintain the property gradation of the semi-finished product or even to introduce it by joining. Suitable joining processes are laser beam welding, friction stir welding and magnetic pulse welding, which will be investigated in more detail in the project.

On November 7, 2019 Andreas Maciolek will give a lecture entitled »Cyclic material behavior of aluminum wrought alloys considering heat treatment and prestrain« at the LightMAT conference in Manchester with current results of the Fraunhofer LBF from ALLEGRO.

Sponsors and partners of the ALLEGRO project are the LOEWE Landes Offensive zur Entwicklung Wissenschaftlich-ökonomischer Exzellenz, the federal state of Hessen, as well as the University of Kassel and the Technical University of Darmstadt.