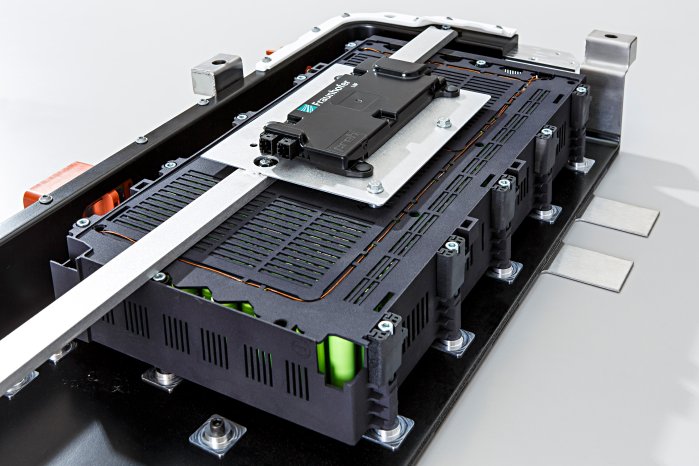

Scientists at the Fraunhofer Institute for Structural Durability and System Reliability LBF are developing battery housings that are as light and recyclable as possible, including those made of plastic for e-mobility. For structural components to be successfully recycled, they must be easy to dismantle and suitable for the material flow to make sorting as efficient as possible. The resulting material flows should be used as efficiently as pos-sible and processed into high-quality recyclates. Using comprehensive analytics, the researchers at Fraunhofer LBF can record the quality and possible batch differences of the materials. This serves as a starting point for targeted material adaptation as part of the R-strategies for use in demanding and highly stressed applications. Adapted additives can improve quality along the entire value chain.

Repurposing old batteries - an opportunity for the industry?

In the "CIRCULUS - sustainable battery system for the energy transition and new busi-ness models" project funded by the German Federal Ministry for Economic Affairs and Climate Protection, the recycling and use of recyclates in battery housings as well as the reuse of old battery cells were investigated. The results show that the battery cells they contain usually still have sufficient capacity and performance at the end of the vehicle's life to be used as stationary power storage in a second life. "This allows us to recycle the materials used and, among other things, enables the resource-intensive battery cells to be used sustainably," says Eva-Maria Stelter, scientist at Fraunhofer LBF and CIRCULUS project manager.

Sustainable development thanks to an interdisciplinary approach

The use of previously used battery cells from former traction storage systems in 2nd-life applications is a complex transformation process. "In order to master this, a transdisciplinary approach is required to discuss the relevant challenges and issues in all their complexity. The different perspectives of various scientific disciplines regarding economic, ecological, and social aspects must be considered," explains Dr. rer. sust. Dominik Spancken, the first doctor of sustainability sciences in Germany. The Fraunhofer researchers have published their findings in a study (doi:10.24406/publica-3054).

Invitation to the panel discussion on June 20 in Amsterdam

Interested parties can learn more about this topic at the panel discussion "Complementarity of Mechanical & Chemical Recycling" on Tuesday, June 20 from 10:40 to 11:25 a.m. in Conference Theater 2, Hall 11.

Customized plastic recyclates - industry can benefit

The Fraunhofer researchers are looking for further partners to develop recycled plastics for demanding applications according to application-relevant requirements. Industrial partners can benefit directly from the new developments and participate in one of the current joint projects, for example "Material and long-term properties in recyclates" or “Design for Reliability - Plastic recyclates in technical components”.