With so-called single-mode fiber arrays, the precise arrangement of the individual fibers is crucial. Up to 32 light-conducting fibers are mounted in several layers in one connector – today, they are usually still glued manually and individually in the connector, since the correct alignment of each individual fiber determines whether the component can perform the desired data transmission.

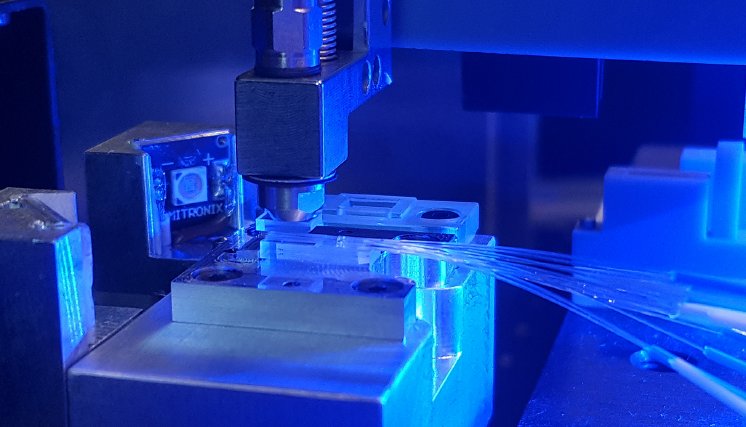

The assembly system can now take over this complex and thus costly task: The system automates all of the essential process steps for manufacturing the connectors – from storage and feeding of the fibers to rotary and translational alignment, gluing and hardening of individual fibers through to final assembly of the entire system into a linear fiber array.

Today, the system can already assemble connectors with up to 16 fiber connections autonomously. Further developments now aim not only to increase the number of fibers processed, but also to improve the handling of the non-rigid fibers and thus further accelerate the entire production process.