Hazardous goods refer to substances that pose risks of fire or explosion. For example, in the automotive industry they are found in airbag systems, belt reels, retractors and anchor pretensioners. Such products can be found in every car, truck, and the increasingly popular electric vehicles and must be handled with special care during transportation.

Strict regulations are in place to prevent risks when transporting dangerous goods. Special containers made for this task feature increased stability and a locking mechanism. This feature greatly reduces risks during transportation. This type of packaging is subject to strict regulations and, after thorough and successful testing, are officially approved as suitable containers and marked with a UN label.

The new dangerous goods container, RL-KLT GGV by SSI Schaefer, meets the special safety requirements for transporting solid dangerous substances. The dangerous goods container corresponds to the regulations for international transport of hazardous goods on roads according to ADR 6.1.3.1. As a type-tested and approved container for the transport of hazardous goods of packaging groups class II and III, it corresponds among other things to the UN Recommendations on the Transport of Dangerous Goods, GHS (Globally Harmonized System of Classification and Labelling of Chemicals). Furthermore, SSI Schaefer commissions an additional safety regulation for the approval of the 6(c) Bonfire Test.

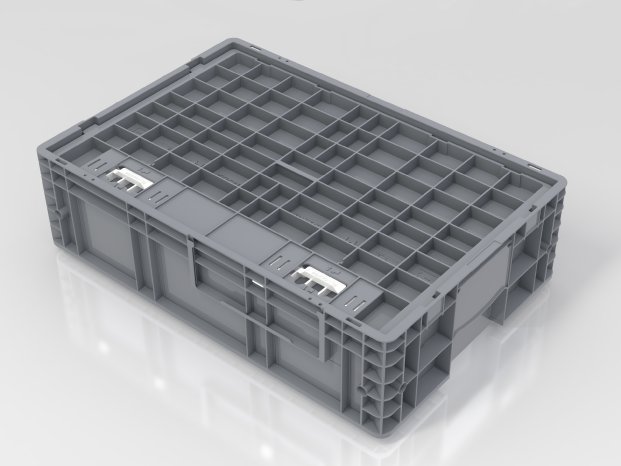

The SSI Schaefer dangerous goods container is featured with stable walls, flat base, and a removable lid. The main benefit of the lid is the locking mechanism, which features a 4-fold lock with spring. Closing the container is intuitive and saves time, since the attachment of straps or other closures is not required. Furthermore, seals on the lock prevent unauthorized access and manipulation of the transported goods. Stowing of hazardous goods in the container can be easily integrated into an existing manual or automatic processes and does not require any additional effort. “The usability of the lid is quite flexible, with the locking mechanism either in the front or the rear, it makes it truly versatile and particularly easy,” explains Jörg Vicktorius, project manager for dangerous goods packaging at SSI Schaefer. “This ensures that hazardous goods don’t fall out of the container or are damaged during transport. Moreover, access to the dangerous goods is restricted due to the locking mechanism.”

The dangerous goods container is available in different heights manufactured with polypropylene, come in an ESD version, and are customizable by attaching labels such as QR or barcodes to the container. It corresponds to standardized European dimensions, which is why it is suitable for stacking on pallets and ensures optimal use of space in the truck. Using individual inserts, such as thermoformed load carriers, the dangerous goods can be centered and fixed in the container to avoid shifting of transported goods. Since the RL-KLT GGV is made of polypropylene, it is reusable and designed for multiple use. Once the container has reached its lifecycle potential, the container is 100% recyclable and is reused to produce new containers.

In the readers' poll for the "materialfluss Product of the Year 2021", the RL-KLT GGV dangerous goods container takes 1st place in the category Containers, Boxes and Pallets. Readers of the logistics magazine materialfluss voted for the products of the year 2021 in eight categories and from 79 nominees by mid-February.

“The new dangerous goods container by SSI Schaefer combines safety with optimized and sustainable handling. The RL-KLT GGV was developed to meet the requirements of hazardous goods transportation, and fits smoothly into existing logistics processes,” summarizes Jörg Vicktorius.