The VT range replaces the models of the ranges GEA Grasso 12, 12E, and 10, which overlapped in their displacement ratings. At the same time, the new and reliable models operate with greater energy efficiency. In comparison to the old two-stage GEA Grasso piston compressors, the energy savings of the new models is up to 9.4 %. The energy efficiency is primarily the result of optimized internal temperature separation and of reduced internal pressure drop. At the same time, the end temperatures at full load have fallen by an average of 5 K, and by 15 K in part-load operation. It was likewise possible to reduce the oil temperature by up to 30 K at part-load operation (depending on cooling demand). As with the single-stage piston compressors of the V range, oil carry-over is extremely low here.

A Maintenance Monitor microprocessor displays upcoming service intervals related to the actual running conditions. This tool represents state-optimized and therefore cost-effective maintenance. The two-stage compression in one enclosure allows a smaller footprint – as well as more favorable investment cost than a combination of separate booster and high-pressure compressors. At the same time, these compressors are economical in life-cycle and maintenance costs, what lowers the total cost of ownership.

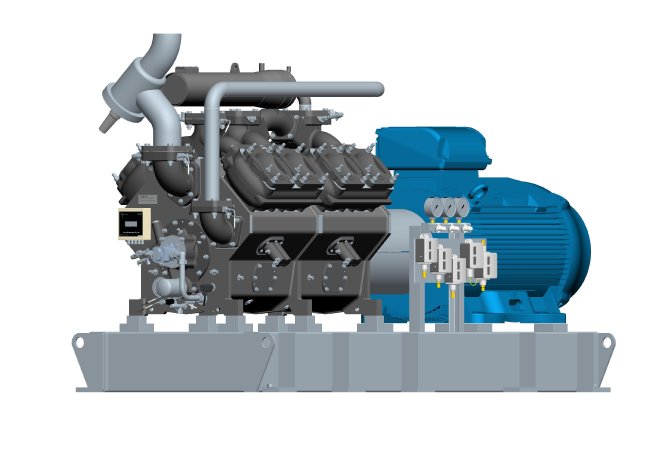

The seven GEA Grasso VT models are available with a completely assembled and patented Economizer. They are also delivered, however, as compact assemblies for installation in machine rooms.