The portfolio of the online shop consists of over 850 international brands and 55,000 products. With the categories perfume, care, make-up, hair care and accessories, flaconi covers all product segments from drugstore to natural cosmetics and premium. With the construction of the new fulfillment centre, flaconi aims to lay the foundation for further expansion with its sustained growth and flexibly meeting future market requirements.

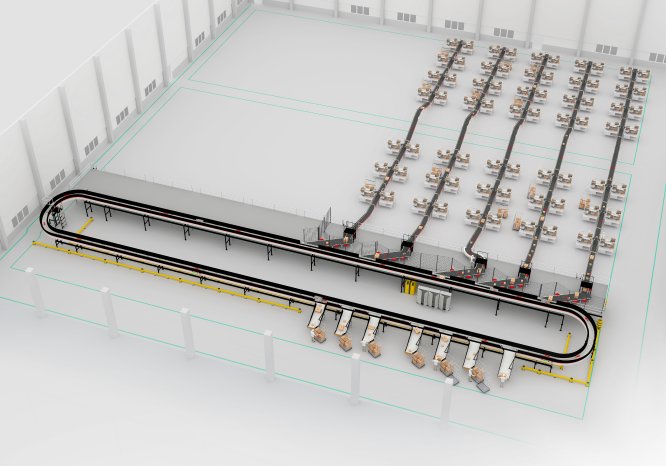

The requirement for awarding the project to GEBHARDT was to include the strong growth in the intralogistics concept and thus offer a custom-fit solution. The scope of supply and services for commissioning included 305 metres of conveyor technology, the new SpeedSorter® developed according to the crossbelt sorter principle, the GEBHARDT StoreWare material flow system and the PLC control.

A large packaging area was created, which consists of the transport of packages, the automated sorting technology and a total of 140 workstations on five pick-up lines. In the future, more than 11,000 parcels can be delivered to the shipping area every hour.

"Thanks to the GEBHARDT SpeedSorter®, we are now able to increase our international footprint and to sort all common European CEP service providers without additional effort. In the end, this helps to further pursue and scale our business model." says Kurt-Alexander Westphal, Team Lead Operations Excellence at flaconi.

The new logistics centre of flaconi is the first ever to benefit from the new GEBHARDT sorting technology, which enables fast and flexible installations thanks to Plug&Play technology. This enables the retailer to react to new market demands and growth with short-term expansions, and thus meet the ever-increasing customer requirements.

Hans Kratz, Team Lead Sales Sorting Technology, adds: "We are very pleased that our product portfolio and the developed solution concept have convinced flaconi and that the company is now well equipped for the future through our innovative automation."