Due to the growing demands for online sales services and the increasing e-commerce sector, manual sorting processes are more often replaced by automated concepts. GEBHARDT recognised this potential and developed a product which optimises the sorting processes based on numerous innovative and digital features.

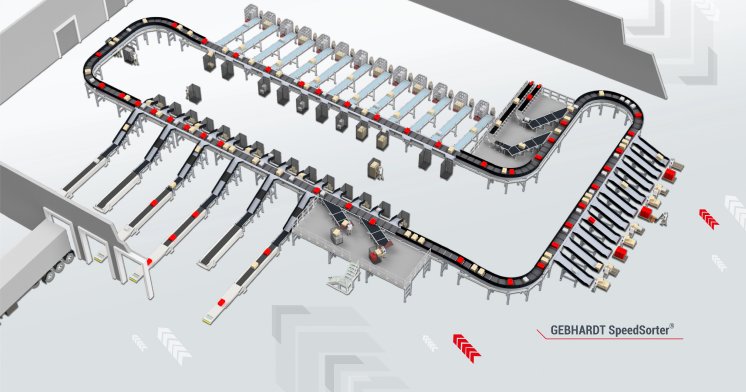

The GEBHARDT SpeedSorter® is based on the crossbelt sorter principle, which enables a continuous material flow concept from a single source through the combination with various system components such as incoming goods, storage, order picking and dispatch. The implementation is advantageous from a business management point of view – the internal material flow can be optimised, and the available space can be used effectively. The digital functions make a lasting contribution to increasing system performance and availability.

This product innovation allows the sorting of a wide variety of conveyed goods at high speed – from clothing and letters to cartons and even food. Totes, packages, poly- and paper bags in different shapes and weights but also longer piece goods can be transported as well.

Due to precise control and the mechanical drive, the entire system is very solid and requires little maintenance. The reliability of the sorting system is ensured by condition monitoring and the associated connection to digital solutions - such as the GEBHARDT Galileo IoT platform. Smart sensor technology, item-monitoring on the infeeds and the interference-free real-time communication between the system control and the sorter components ensure increased precision in the infeed, transport, and outfeed of the conveyed goods.

Proven GEBHARDT technologies such as the GEBHARDT StoreWare® warehouse management system, the integration of the GEBHARDT Galileo IoT platform and the intelligent sensor technology for digital data acquisition ensure a smooth operation of the sorter system and increase the productivity of the entire system.

The system status of the GEBHARDT SpeedSorter® is continuously monitored. The data of the condition monitoring is used for preventive maintenance by predicting the maintenance time of individual sorter components through the application of intelligent algorithms and the analysis of various operating parameters.

In combination with a GEBHARDT shuttle storage system, the GEBHARDT SpeedSorter® can be used as a conveyor technology in the pre-zone of the warehouse. This enables a highly dynamic overall system with maximum picking performances at "goods-to-person" workstations. Thus, the storage system is best equipped for future growth.

With the GEBHARDT SpeedSorter®, GEBHARDT combines economic, operational, and technical advantages of crossbelt sorting technology and thus proves its many years of experience in the development of efficient intralogistics solutions.

The combination of solid, innovative, high-performance technology and intelligent control enables GEBHARDT customers to meet today's requirements, especially the increased capacity needs and required throughput rates.