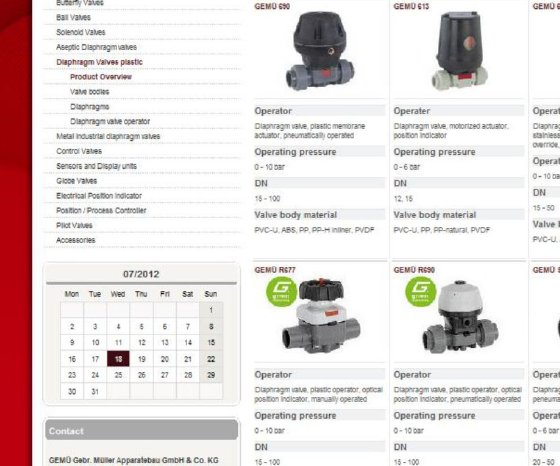

For example, the geometry of the bodies and actuators of our 690 and 677 products was redesigned, which allowed a material reduction of up to 50 % on valves of the same nominal size. The latest R690 and R677 products impress through the resource and cost savings which they enable as well as through their compact, environmentally friendly and high-performing design.

Accordingly, both products have been awarded the GEMÜ GREEN ENGINEERING "Green Logo" - an award for products which, while providing top performance, also make a contribution to the environment and future generations. Gradually, all products which save resources in production, during plant engineering or during operation by the customer will receive this logo.

"Green Engineering"

A tradition of environmental awareness: whether it be the 50% reduction in material used by the first GEMÜ valve compared to conventional valves, or the introduction of a recycling system in 1979 - GEMÜ management and employees have always made efforts to save resources in the long-term. In 2011, Gert Müller, Managing Director of Engineering and Sales, combined these activities under the label GREEN ENGINEERING with its three pillars of CLEAN PRODUCTION, CLEAN PRODUCTS and CLEAN PROJECTS.

In the area of CLEAN PRODUCTION, GEMÜ has been working since the 1970s to save material and energy during production and the company also introduced binding environmental targets in this area in 2009. Possible projects are consistently identified and then put into action in an ambitious manner. This process is then checked during an annual audit and, since 2010, these efforts have been honoured with the (re-)awarding of the EMAS certificate. This makes GEMÜ the only valve manufacturer in the German-speaking world which pursues this demanding and long-term improvement process. Other companies which undergo this audit can be found at http://ec.europa.eu/....

In the area of CLEAN PRODUCTS, there are two approaches towards the development and operation of products: on the one hand, the products themselves should consume less resources during production compared to predecessor products or other products and, on the other hand, they should allow our customers to achieve material and energy savings. Here, the focus is on combining the functionality and reliability of the products and plant design with environmental aspects in order to find solutions which meet all of these criteria.

Gert Müller introduced CLEAN PROJECTS in 2011 when he took over as managing director. The first activity involves testing the use of an Opel Ampera as a GEMÜ electric shuttle for plant transport between our three German sites. Further projects for using new technologies and introducing innovative collaborations will follow.