The condition monitoring system “Peakanalyzer” is a development of GfM. It uses the normal operating movements of the crane. Therefore no specific rides are required. This is realized by monitoring the speed of the rotating drive elements and when reaching the specific diagnostic conditions, the measurement will start. After the measurement a plausibility check is carried out, which guarantees that the valid measuring signals with sufficient length are present. If this is not the case, the measurement is rejected and it is waited until the respective diagnostic conditions are reached again.

From the now measured and plausibility tested time signals, the order spectra and the envelope order spectra are built. These are subject of a DVS-analysis and it is searched for typical damage patterns. If such patterns are not found, the data will be discarded. However, an alarm is generated and the measuring data are stored.

The support of the condition monitoring system is carried out from Berlin. Here, alarms are indicated and verified by the diagnostic experts of GfM. Only then, the system operator is informed. At any time, the support of the system can be carried out by HKM or a third party.

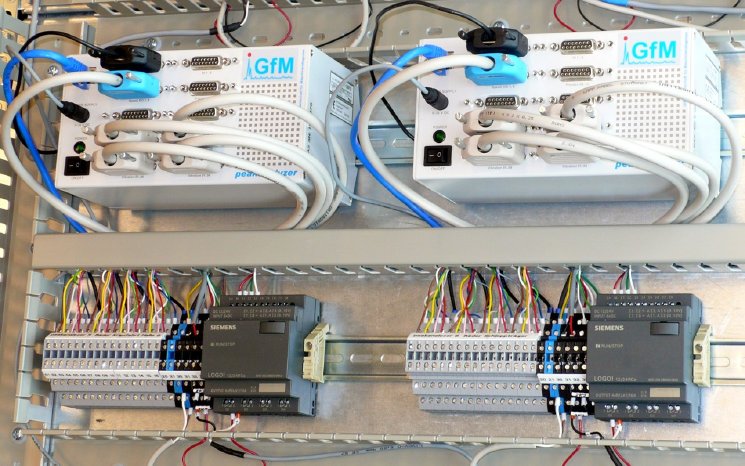

The installation of the accelerometers and the entire laying of the cables will be performed by HKM. GfM is responsible for the installation of the pre-assembled Peakanalyzers in switch cabinets and the commissioning.

The DVS-analysis – a patent pending method for the automated machine diagnosis, ensures that the condition monitoring systems are able to work immediately without a learning phase.