THE TEAM GETS READY

Damir Stimac, GCS Sales Manager Croatia, led and coordinated the project with CROMAC-CTDT at the Cerovac test site, around 60km south of Zagreb. “I am feeling very confident about the days ahead,” said Stimac, “the GCS-200 remote-controlled platform represents the latest technology in mechanical mine clearance and outperforms any similar mechanical system on the market.” The GCS-200 machine and the tiller attachment were transported to the test site from Germany by Christopher Thompson (our GCS-200 Senior Technician) and a team of GCS experts, with a fully equipped mobile service van. Upon arrival, the CROMAC-CTDT test leader, Mr. Ivan Steker conducted a pre-test inspection of the GCS-200 machine and supporting equipment and the green light was given to proceed with the testing. The tests were conducted in accordance with the CWA15044:2009 and IMAS 09.50 for safe, efficient and effective mechanical demining.

PERFORMANCE TESTS

Following careful preparation of the site, the GCS-200 went up against the first round of tests – a thorough evaluation of the performance of the machine in three different soil topologies (sand, gravel and topsoil). The GCS-200 performed excellently in the three consecutive test lanes, demonstrating a continuous and consistent penetration on all soil types and at required depths at efficient speed. The day concluded with a vegetation clearance test, where the GCS-200 was evaluated for its capacity in clearing varying densities of vegetation; low, medium and high. The GCS-200 successfully cleared a few hundred square meters of vegetation in all scenarios. The tiller attachment cleared individual trees of up to 15 cm in diameter without any damage to the equipment.

COST EFFICIENT AND ROBUST

The intensity of the tests increased significantly over the course of the following days, with the GCS-200 enduring several challenging live mine test scenarios. Survivability and acceptance tests were carried out using 3 Anti-Tank (AT) and 19 Anti-Personnel (AP) blast and fragmentation mines, with some mines activated by pressure and others by tripwire or tilt rod. The robustness and efficiency of the GCS-200 proved irrefutable – the machine successfully neutralised all 22 mines with the help of the tiller attachment. Despite the enormous blasts and fragmentation of two of the AT mines, (which are specifically designed to destroy vehicles including tanks and armoured fighting vehicles), there was only very minor damage to two chisels and two chisel holders on the tiller attachment. The GCS-200 machine and tiller attachment continued to operate exceptionally without any issues. Our technicians only needed 10 minutes to fit replacements with the cost of material amounting to less than 350 Euros.

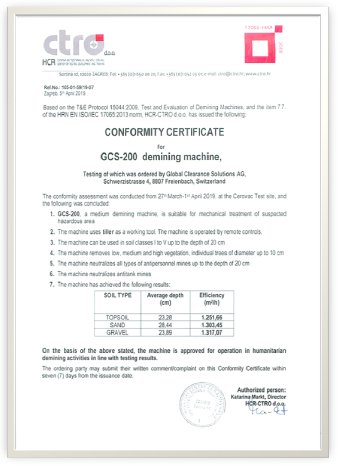

GCS-200 IS CROMAC CERTIFIED

The first-rate performance of the GCS-200 lead to the successful accreditation certificate from CROMAC-CTDT for safe, efficient and effective mechanical demining in all types of soil, for clearance of all types of vegetation, and for mechanical demining of all types of AP and AT mines. “The GCS-200 machine provided excellent results against all test criteria without any malfunction or issues during the testing and accreditation”, said Stimac. “This reflects GCS continuous commitment to enhance the reliability, productivity and safety of mine clearance operations and disposal of explosive remnants of war (ERW). By deploying its cutting-edge equipment alongside its highly-skilled certified staff, GCS can ensure that the very highest mine clearance standards are adhered to.”