The jumbo glass coater is available for Research & Development as well as for any tasks of laboratory nature. The Coating-Lab is ready to handle jumbo size glass substrates widths for all major application areas and the relevant coatings for high-end products. Starting with dielectrics (e.g. Si3N4 or TiO2), ultra-thin metal and barrier coatings (e.g. Ag and NiCr), up to coatings for special applications in the display and solar industry, as well as transparent conductive coatings (ITO, ZnO, ZnMgO). The Coating-Lab, type GB 3300 for jumbo size glass offers all properties of a production plant and is equipped with leading edge technology of todays large area coating industry.

Strengthening position within coating sector

"With the new Coating-Lab we emphasize the strategic meaning of the coating sector for our company. With the application of the most recent technologies and ongoing development, we continuously strengthen our leading position within the flat glass sector. Our experts in the Coating-Lab are available to our partners and customers to answer difficult questions as well as to provide training", says Renato Luck, CEO of the Grenzebach Group. With Soleras Advanced Coatings with its headquarters in Belgium and Advanced Energy Industries with its headquarters in the US State Colorado, we have strategic partners with extensive experience and technology know-how to drive forward innovative technologies on an international level.

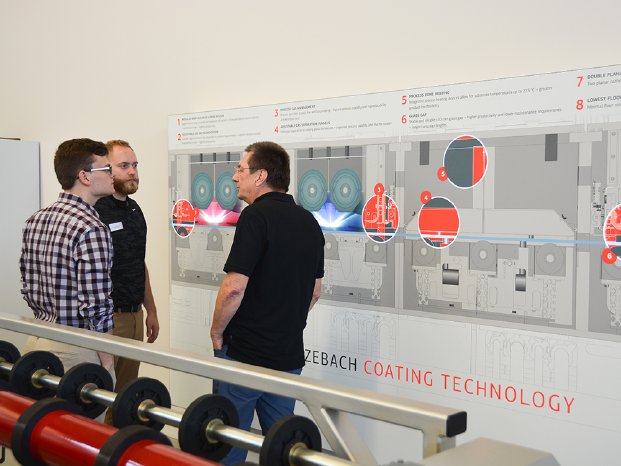

Coating Competence Days with 30 participants

During the Coating Competence Days mid-October, 30 industry visitors could take a closer look at the potential of the new Coating-Lab. How can large area coating further be optimized? How can newest innovations for energy conservation purposes be implemented? These are the type of questions experts from Grenzebach together with partners and customers focused on in the new Coating-Lab headquarters in Hamlar near Augsburg. Right here difficult topics about coating technology can be discussed and solved. Testing new hardware components in the Coating-Lab as well as samplings are possible. Furthermore, Grenzebach offers a professional training environment for all who are interested. "Together with Soleras Advanced Coatings and Advanced Energy we can utilize our new lab to look into coating technologies of tomorrow", says Egbert Wenninger, Senior Vice President Business Unit Glass.

Use revision times even more efficiently

The team around Dr. Jens Ellrich, Head of Coating Technology at Grenzebach, impressively demonstrates the immense influence of efficient revision procedures and shortest possible maintenance times on the efficiency of coater lines. SERICY, the digitization platform developed at Grenzebach, opens new avenues. Furthermore, with the use of digital instruments, the performance of coating lines with regards to quality and quantity can be developed further.

With SERICY into the Factory of Tomorrow

With SERICY Grenzebach has developed a platform, which allows digital solutions and new features with tangible added value for the customers - solid steps towards the Factory of the Future. With the IIoT platform all sequences in production, the warehouse and the shipping department can be controlled; equipment parts and devices of numerous manufacturers can be integrated. Data management and analysis enable the users to continuously develop the production based upon their own information. The integration of data of the coating line provides extensive process control, which in the future will allow almost complete automation also within the field of coating technology and set new standards in economics. Only the implementation of the most recent methods for data logging, saving and analysis allows this quantum leap. Grenzebach experts indicated how digital technology helps to improve the process performance of coaters in the chambers and coating stations. With apps which are running on the SERICY platform, a series of assistance systems for employees to use in the coating sector are possible. The spectrum reaches from the Maintenance Manager for planned system maintenance to the Settings Manager saving machine settings and providing a time stamp.

The Grenzebach portfolio also includes up-grades and handling technology

The fully automated PVD coating equipment from Grenzebach allows the production of all demanding coatings required at todays market for large area glass products - from sun protection applications to high-quality insulating glasses (Low-E coatings). For the worldwide customers, the experts from Grenzebach continuously push developments within the field of PVD coating and take care of the installation, commissioning and production start of new coating lines. Aside from the core of the equipment, the coater, Grenzebach implements conveyor, cutting and handling technology. Needless to say that comprehensive upgrades of existing systems are also part of Grenzebach's portfolio.