"As a leading provider of interim management and experts in Asia, GTEC and its team need to stay ahead of industry applications in order to provide excellent service to its clients. Therefore, attending exhibitions and congresses is a must to get in touch with other companies and their leaders to learn what they are offering in the market," said Karlheinz Zuerl.

Today's press release is aimed at C-level executives attending the Future Energy Asia conference in Bangkok, May 15-17.

"We offer a wealth of expert analysis that enables readers to make informed decisions, seize opportunities and thrive in the ever-evolving Asian market," summarizes Karlheinz Zuerl.

Future Energy Asia focuses on low-carbon societies and decarbonized energy ecosystems. The Asia-Pacific region is the world's largest energy market, already accounting for nearly 50% of global energy consumption. With projections for rapid economic and population growth in the coming decades, the world is seeking to meet the critical goals of low carbon footprint and decarbonization.

For example, STRATEGICS EXPERTS from Malaysia and Bharat Petroleum Corporation Limited from India.

1. About STRATEGICS EXPERTS

Founder and CEO L. Shaktivell said: "We are committed to transforming industries through innovation and sustainability. For example, in Gas & Oil, our Fiber Comp. is revolutionizing maintenance practices for piping systems through Smart AI Predictive Maintenance and Composite Wrapper technology".

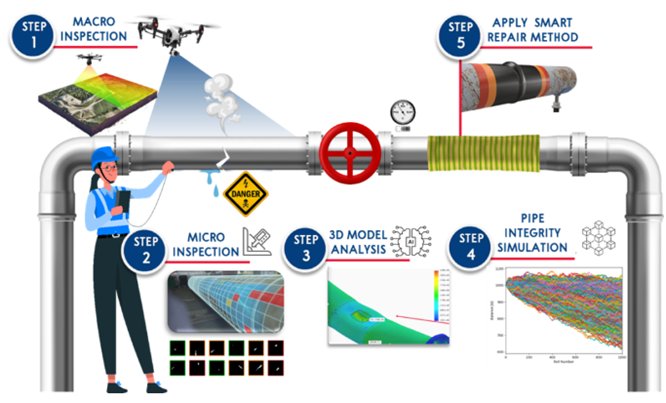

61% of pipe leaks are caused by corrosion, resulting in $30 billion in lost revenue annually. Currently, when a pipe leaks, there is an emergency shutdown and the pipeline needs to be closed and repaired. Their solution has the following steps:

- Macro inspection by drones, send data to base station. Monitored by cloud computing.

- Micro inspection

- 3D model analysis

- Pipe integrity simulation

- Apply intelligent repair method simulated with AI integration.

- Shaktivll explained: "After 3D inspection of the defective pipe, we use our AI imaging system to categorize the condition of the structure and evaluate the severity. Solutions are generated by our AI prediction. We validate the suitability of the proposed solution using blockchain technology."

"Computational simulation, CFD analysis and simulated wrapper selection with calculation of maximum stress on the repaired pipe, lifetime prediction with GFRP and CFRP wrapped pipe. In our case study, CFRP reduces the average crack growth rate to 60% of the base rate, while GFRP reduces it to 50% and shortens the service life. Therefore, the average emission (kg * CO2) of a CFRP wrapped pipe is the lowest," summarizes L. Shaktivell the cost efficiency of AI and blockchain application through optimized maintenance operations.

Past projects of AI inspections and preventive maintenance applications have also been in solar panels, marine structures, aircraft.

See details at https://strateticsxp.com/

2. About Bharat Petroleum Corporation Limited

A Fortune Global 500 company, Bharat Petroleum is India's second largest oil marketing company and one of the leading integrated energy companies in India.

Santanu Purohit presented the lack of cyber security and the thread of hackers. The gap between IT and OT networks is shrinking as software-based connectivity increases. Assets that were once monitored by handheld devices and standalone sensors are now being integrated into the connected enterprise network to gain valuable insights from machine data. The increased reliance on web-based communication and technology has opened the door to cybersecurity threats. These threats are prevalent in industries such as healthcare, banking and financial services, government and defense, education, and energy and utilities.

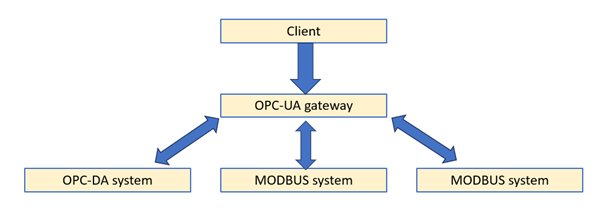

In India's oil and gas industry, the storage and supply chain is currently automated using MODBUS and OPCDA protocols. And there are significantly fewer layers of security available in the protocols. With the increasing digitization and narrowing of the IT-OT gap, the MODBUS protocol needs to be upgraded with security layers. See the case study below:

Attackers gather information about the target's supply chain, identifying key suppliers, software vendors, and third-party service providers. They analyze network and system architectures, looking for connections that rely on SCADA and MODBUS communications.

Attackers infiltrate less secure elements of the supply chain. This can include inserting malicious code into software updates. The malware performs predefined tasks such as opening backdoors, collecting sensitive data, or waiting for further commands. It can remain dormant until triggered externally, reducing the chance of detection.

Attackers can steal sensitive operational data, manipulate industrial processes, or lay the groundwork for a major disruption. Alternatively, attackers could use ransomware to lock down systems and demand payment to restore access.

The solution is to choose a more secure, more functional network such as OPCUA.

An OPCUA gateway adds a robust layer of security to existing MODBUS systems. By centralizing security management, it reduces the need for multiple upgrades to legacy systems, significantly reducing costs. The gateway enables secure, encrypted communications. Monitoring increases the overall network's resilience to external threats. The gateway minimizes the risk of disruptions and breaches, providing cost-effective, long-term protection.

See details at https://www.bharatpetroleum.in/

Contact details

contact@gtec.asia

https://gtec.asia