When it comes to force and torque measurement technology, there are times when even high-precision standard transducers just won’t cut it. If, for example, you need to simultaneously measure forces and torques along multiple vector axes for automotive, medical or robotics applications, you’ll often be better served using GTM multicomponent transducers.

For challenging measurement jobs: multiple axes lead to success

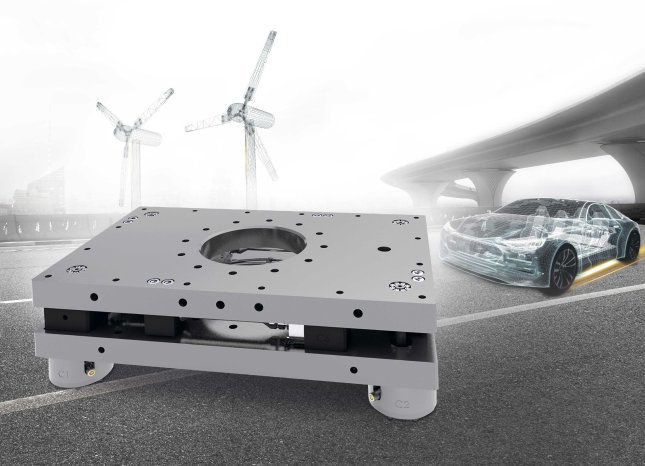

MPF-series multicomponent measuring platforms are designed for high-precision multicomponent measurement of forces and torques along the three axes (x, y, z). The MPF series features several separate high-precision force transducers. These are meticulously aligned and mechanically decoupled from one another. This ensures multicomponent measuring at maximum accuracy. Thanks to the inherent immunity to interfering loads, MPF measuring platforms are excellent for tackling even particularly challenging jobs.

Support and service throughout entire lifecycle

When designing a multicomponent measuring platform, GTM works closely with the customer to tailor it specifically to its actual use case and then manufactures the equipment specially. The multicomponent measuring platform is fitted with the exact number of force transducers required by the customer or application in question. In most cases, there will be six, seven or eight separate precision force transducers. Each multicomponent measuring platform is sized to match the project’s connection dimensions and loads expected.

Typically, MPF-series multicomponent measuring platforms will be used where sensitivity and accuracy required differ considerably along the various axes. This would be the case in wind tunnels or rolling resistance test benches, for example. To round it off, the overall package for GTM’s customers includes matching multicomponent precision signal conditioners for all-in-one measuring chain solutions, extensive calibration services and best-in-class support throughout the product’s entire lifecycle.