This FTIR engine will be on display at the exhibition running in parallel to the International Conference “SPIE Photonics West 2020” held in San Francisco, California, United States, for 3 days from February 4th to February 6th.

Product Overview

The C15511-01 FTIR engine is compact enough to carry in just one hand. A Michelson optical interferometer (*) and control circuit are built into a palm-sized enclosure. FTIR engine has high sensitivity to near-infrared light at wavelengths from 1.1 to 2.5 μm.

FTIR spectrometry is a chemical analysis technique that makes use of an optical interferometer.

A sample is irradiated with infrared light and the intensity of transmitted or reflected light is measured for each wavelength to analyze and determine the composition of substances contained in the sample. Currently, most FTIR spectrometers are bulky bench-top instruments that are widely used in laboratories and specialized agencies or institutions. However, there are increasing demands for a compact but high sensitivity FTIR engine needed to create portable handheld analysis equipment that can be easily used at measurement sites.

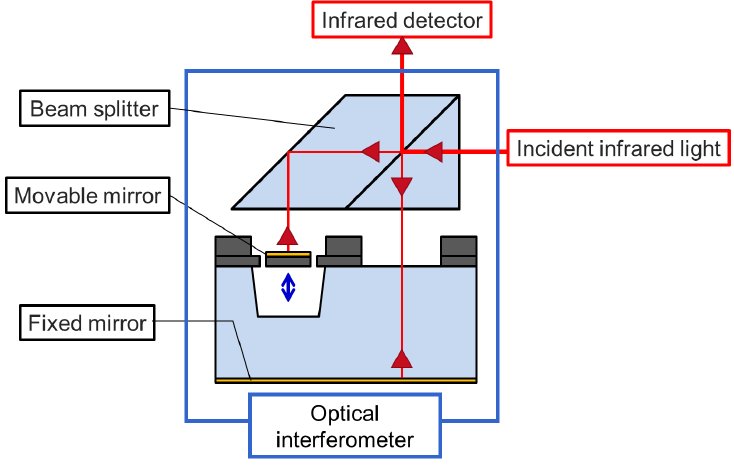

* An optical interferometer is an optical device designed to produce bright and dark fringes of light (interference) by splitting light into two or more beams and reuniting them.

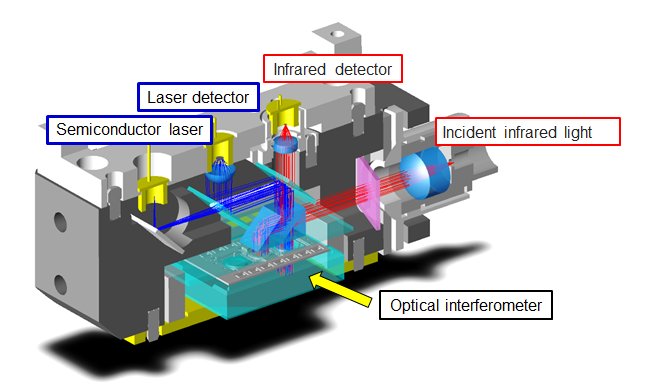

Structure of FTIR engine (left) and optical interferometer (right) used in FTIR engine

Since the optical interferometer takes up most of the space in an FTIR spectrometer, we reviewed the optical interferometer design from scratch to make its size much smaller by using our own unique MEMS technology.

MEMS technology enabled us to develop a very small but large-diameter movable mirror that resolved the challenge of how to shrink the interferometer size without reducing the amount of infrared light to measure. Our advanced mounting technology also integrates optical components such as the movable mirror and fixed mirror into a compact shape that also minimizes the error in the relative angle between the mirrors.

At the same time, we optimized the driving mechanism for the movable mirror to prevent infrared light from diffusing in the optical interferometer and in this way reduced light loss. All of these efforts helped us succeed in developing an optical interferometer that utilizes infrared light very efficiently despite its small size.

This optical interferometer is combined with photodetectors and assembled into a palm-sized package that serves as a compact, high-sensitivity FTIR spectrometer. Moreover, we used a semiconductor laser to precisely detect the position of the movable mirror to enhance reproducibility of measurement results.

Our FTIR engine will help create portable handheld analysis equipment that detect near-infrared light at wavelengths from 1.1 µm to 2.5 µm and still offer high sensitivity equivalent to that of bench-top instruments, making them a promising tool for chemical component monitoring on production lines to improve productivity and product quality. Other applications may include inspection and sorting of agricultural products in the field by analyzing their ingredients and identification of plastics in recycling plants that contain additives such as flame-retardants. We also release software that comes with our FT-IR engine for setting measurement conditions, acquiring data, and displaying data graphs.

To meet further market needs, we will continue to improve this FTIR engine to further reduce its size and extend its spectral response to longer wavelengths.

Main product features

1. Compact, high sensitivity FTIR engine

We reviewed the optical interferometer design from scratch and developed a tiny movable mirror of 3 mm diameter by applying our MEMS technology. This enabled us to overcome the challenge of shrinking the interferometer size without reducing the amount of infrared light to measure. We also put the optical components together into a compact shape by directly bonding the movable mirror and fixed mirror with our advanced mounting technology and in this way succeeded in reducing the error in the relative angle between the mirrors to about 0.01 degrees. Moreover, we optimized the actuator structure and drive method for the movable mirror to eliminate the blurring that occurs when driving the mirror. This suppressed the diffusion of infrared light in the optical interferometer and thus reduced light loss. Our FTIR engine will therefore prove a powerful tool for creating portable handheld analysis equipment that can be downsized to 1/100th of the size of bench-top instruments yet have equally high detection sensitivity to near-infrared light at wavelengths from 1.1 µm to 2.5 µm.

2. High spectral reproducibility

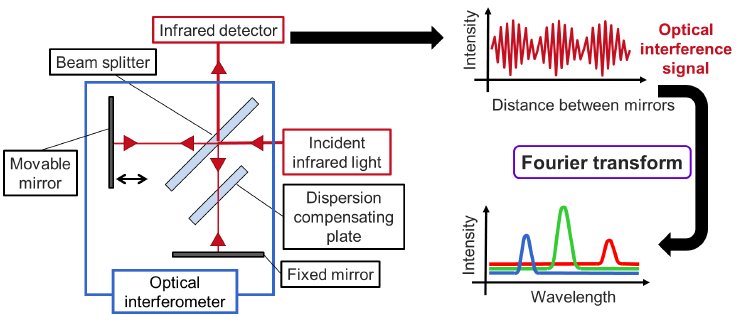

The FTIR spectrometer performs Fourier transforms based on the interfering light (optical interference signal) and the position information of the movable mirror to calculate the intensity of infrared light for each wavelength. Our FTIR engine utilizes a semiconductor laser to detect the precise position of the movable mirror so that measurements can be made with high reproducibility.

How an FTIR spectrometer works

Infrared light has the property of being absorbable at a specific wavelength determined by the vibrational energy inherent in molecules. Each molecule can be identified by utilizing this property, so the spectral range of infrared light is often called the “fingerprint region” of molecules and is widely used in analytical spectroscopy.

Infrared light entering an FTIR spectrometer is divided into two beams by the beam splitter in the optical interferometer. The two beams are each reflected by the fixed mirror and movable mirror and reunited by the beam splitter. The light is then detected by the infrared detector as an optical interference signal. Based on the position information of the movable mirror and the optical interference signal that changes its intensity according to the position of the movable mirror, a Fourier transform is performed to calculate the intensity of infrared light for each wavelength to analyze the components of the sample.

For further information contact us on email: europe@hamamatsu.de or visit our website: www.hamamatsu.com