To comply with the increased requirements on windows and meet the European target of dramatically reducing the energy consumption of buildings by 2020, the passive house capability is becoming ever more important also for window connections.

For this reason, this requirement was also included in the Directive WA-15/2 of ift Rosenheim which addresses the passive house capability of windows, external doors and facades. However, heat loss requirements at connections of the body shell are also defined.

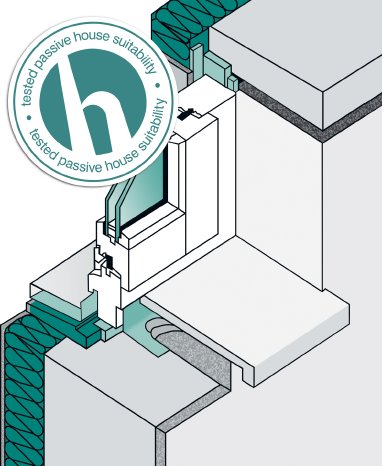

The Hanno® 3-level joint sealing system has been known to the market for its high quality and practicability for many years. After the directive had been published, it was important for HANNO to prove that this system also complied with the theoretical requirements for the calculated evidence. For this reason, different application and design versions of the products of the Hanno® 3-level joint sealing system were tested by the internationally well-known BBS Institut Wolfenbüttel of Prof. Dr.-Ing. H.P. Leimer on the basis of the ift Directive.

The result was more than convincing. The BBS Institut Wolfenbüttel confirms: „The joint sealing systems of the company Hanno Werk examined can be considered to be passive house capable as intended by the ift Directive WA-15/2. For conventional installation situations of the windows in passive houses, the joint sealing systems meet all requirements of the ift Directive WA-15/2.

HANNO is proud to underline once again its position as leading supplier of sealing products and the sustainability of the known products by the early and external documentation of a very renowned institute without problem.

Asked for the target of this and other examinations, Dipl.-Ing. Björn Kethorn, HANNO Application Engineering Manager, says:

„For us it was important to show that our products already now meet the stricter requirements on energy efficiency expected for the future. I guess we have been quite successful in this respect. We see this test as part of a series of further studies, tests and examinations for the permanent sealing of connection joints.

The mere statement that a joint was airtight, resistant to driving rain or heat insulating in one or another test is simply not enough under today’s high requirements. It is important that these characteristics are maintained for a long time, especially because the movements of the joints become larger due to the bigger size of the building elements and the temperature differences. I believe that in this respect we are very well positioned with our products.“