One of the fundamental ideas behind Industry 4.0 is to implement production facilities, for example, assembly cells, on the basis of intrinsically intelligent automation components, so-called Cyber Physical Systems (CPS). A complete production job is then carried out either through automatic control and optimization of the components among one another or through the coordination of a superimposed system.

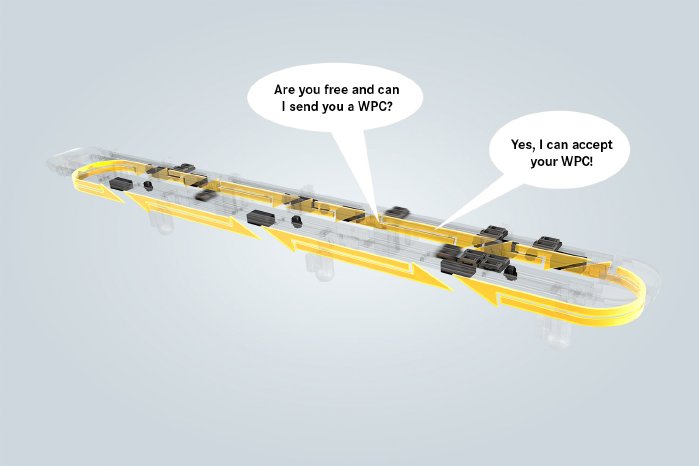

For example, this could be the control of workpiece carriers (WPC) on a conveyor belt. HARTING Applied Technologies has developed the "intelligent stop point" for the company's own HAII4YOU Smart Factory. Each stop point has an Ethernet communication interface with its own switch, which allows the "intelligent stop point" units to be chained to one another in any way.

All inputs and outputs for the administration and function of a stop point are furthermore included. Integrated valves actuate the necessary pneumatic components. Depending on the environment's requirements, a stop point ensures the smooth flow of the product carriers or it clamps the workpiece carrier (WPC) in a defined position for processing. In the first case there is direct communication among the participating "intelligent stop point" units. In the second case, the ISS coordinates with the coordination level. The material flow is under control without additional programming. It is only necessary to provide all intelligent stop points with initial configuration during the installation.

HARTING will be showcasing the functioning solution within the HAII4YOU system at the SPS IPC Drives trade fair.