HARTING is driving development forward in Ethernet connectivity for the networks of the future. Single Pair Ethernet (SPE) is a hot topic in the market for industrial cabling. HARTING provides the right standardised interfaces for this and will be showcasing the first serial products at HANNOVER MESSE 2019, making the leap as a pioneer of Industrie 4.0 from a technology trend to real-life application and a customer-specific solution. "We are following our own consistent path with an IEC standardised interface: recognising trends, defining standards and delivering reliable products," says Frank Welzel, Director of Product Management, HARTING Electronics. The HARTING stand will include the first IP20 interface consisting of a connector and a PCB socket.

The core of this new HARTING T1 Industrial series is a standardised SPE mating face that can be used for all housing variants from IP20 to IP65/67. HARTING has adapted its connector concept to future requirements and can handle 1GBit/s for shorter routes as well as 10Mbit/s for longer distances with one standardised mating face.

HARTING RJ Industrial® MultiFeature series

With RJ Industrial® in the new MultiFeature series, HARTING has been able to fulfil its customers' wishes and requirements for even easier operation and assembly in the field. Further development of the successful RJ Industrial® standards has resulted in tool-free assembly, simple operation and a robust metal housing. The ability to use these for AWG 26 to 22 wire strands and their robust cable attachment are properties that make installation easier and quicker for the installer. While the classic RJ45 was a telecommunications development that was not enough for every industrial demand, the HARTING RJ Industrial® MultiFeature series can cope with all the requirements and challenges of a hard operating environment. Safe Cat. 6A performance, IP20 and IP65/67 housing combined with PoE power supplies IEEE802.3af (PoE 15.4W) / IEEE802.3at (PoE 25.5W) / IEEE802.3bt (PoE 100W) supply data and power for any device.

M12 PushPull meets IEC 61076-3-126 / IEC 61076–2–010

Dr. Metrix is the new face of time-saving PushPull interlock mechanisms. HARTING's new heroine represents clever PushPull technology on metric circular connectors and connection in seconds. Dr. Metrix first provided a comprehensive M12 PushPull solution for factory automation on SPS IPC drives. It will continue its mission at HANNOVER MESSE 2019, jetting into the future with one click.

Finding the right general standards for M12 PushPull interlock mechanisms will now be easy as part of the standardisation work actively driven forward by HARTING. This will make customers feel more secure about their investments, as well as meeting the requirements of the M12 as a recognised standardised interface. Previous solutions have engaged on the outside of upright device sockets with a characteristic click, HARTING will be presenting a new M12 PushPull interface for recessed sockets at SPS 2018 for the first time. Sockets of this connector type are widely used in automation. They have an internal lock and can be installed very flat to the surface without external collars. Miniaturisation is one of the key requirements of the automation sector.

More and more industrial connector technology manufacturers are relying on time-saving PushPull concepts for their connectors that are easy to operate. The classic screw lock of the M12 circular connector always takes a huge amount of time to install when assembling multiple interfaces. In a direct comparison of the M12 PushPull to the traditional screw lock, the new interlock technology can be connected around 75% faster.

Automation requirements focus on simple and safe operation, acoustic feedback and savings in terms of time and costs. HARTING can now meet all these requirements and is working alongside market competitors to drive forward the standardisation of a comprehensive M12 PushPull market standard. This should result in an IEC 61076–2–010 and IEC 61076-3-126 standard that ensures a comprehensive solution for factory automation, ensuring the security of investments and second sources for users.

Standards benefit everyone

Standard is the main keyword for all the highlights at Hannover Messe. Although proprietary solutions can be just as good, they usually remain an isolated solution in the long term. Investment security, a recognised form factor for the device and familiar operation are positives for everyone along the value chain. Standardised mating faces, easy assembly and simple operation in the field benefit everybody. "Standardisation helps the CEO of a company, the constructor and, not least, the user. Everyone feels like their plans are more secure," says Frank Welzel.

Compact, robust and rectangular: Han® 1A

The Technology Group has also come up with innovations for heavy-duty connectors: the Han® 1A is a new compact and extremely robust rectangle connector that can handle data, signals and power with up to twelve contacts. It is made from high-performance plastic, is light and takes up very little installation space.

Given its modular construction and range of different uses, it is particularly suitable for use in areas where a supply is needed for multiple small drives, sensors and devices.

In machinery, Han® 1A facilitates the efficient combination of tools and modules such as heating or cooling units, fans, control terminals, lighting systems, drives, vibration conveyors and similar equipment. In traffic technology, you can use Han® 1A to connect door drives and access systems, as well as lighting, headlights, loudspeakers, screens, display panels, warning and alarm lights, push buttons, acoustic signals and windscreen wipers.

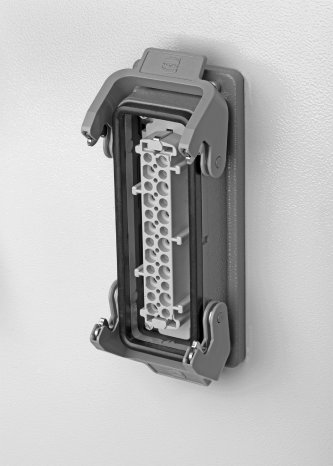

Han® metal housing for simpler control cabinet assembly

HARTING now offers the metal housing for the Han® B, EMC and M series in versions that allow the rear assembly of contact inserts. The new option makes it easier to assemble interfaces for control cabinets, aimed particularly at applications in machinery and automation, robotics and traffic and energy technology.

Han® connectors with metal housing are the ideal match for environments with high requirements in terms of component robustness and the simplest possible installation. Until now, the assembly of Han® metal housings required the cable to first be fed through an opening in the control cabinet so that the inserts could be assembled outside the cabinet and pulled back into the bulkhead housing. The new Han® solutions also allow for pre-fabricated inserts to be locked in place directly in the bulkhead housing – from the inside of the control cabinet.

Hygienic and safe: Han® connectors for the food industry

With Han® F+B, HARTING has created a range of connectors specifically for the requirements of the food industry. Smooth surfaces make it harder for bacteria to accumulate. The housings and seals are robust, safe and long-lasting: they prevent the internal contacts coming into contact with the water from high-pressure cleaners or aggressive cleaning agents.

Hygiene and safety are decisive factors in food processing: the junctions, surfaces, threads and seals of the Han® F+B connectors were therefore designed in a way that makes it harder for dirt particles to stick to them. Round curves on the housings and accessories prevent the build-up of dirt pockets that are an ideal breeding ground for bacteria.

Han® F+B housings are made from high-performance plastic and are water-repellent and suitable for cleaning agents. They are certified by Ecolab and have FDA 21 licences. The water flow from high-pressure cleaners cannot get into the housing as long as it remains closed.

Update on Han® Configurator for industrial connectors

HARTING introduced its Han® Configurator for industrial connectors at Hannover Messe last year. The intelligent system allows customers to generate concrete suggestions for custom-fit interfaces on the basis of a few entries. We will be showcasing new functions and extensions at the trade fair this year, such as optimised 3D display of the relevant configuration results.

HARTING accelerates e-mobility:

The HARTING stand in Hanover will be also be presenting the "microSNAP", the latest vehicle concept from Swiss automotive visionary Frank M. Rinderknecht. The bold idea behind "microSNAP": the quick removal and replacement of the chassis, drive ("Skateboard") and bodies ("Pods"). Together with Kuka, HARTING will be presenting a corresponding robot-operated charging station for quickly recharging batteries. A Kuka robot connects the HARTING charging plug and ends the charging process when the drive battery has reached the required charge level. This means that the vehicle is ready to use again in a very short space of time. A solution with plenty of areas of application.