Good things have now come to those who waited. Having previously presented initial models at the SPS exhibition, HARTING will use this year's Hannover Messe trade show to launch the full M12 Power portfolio. The L-encoded variant makes more than enough power available to energy-hungry applications. At the same time, the new M12 Power standard IEC 61067-2-111 means the power connector shines with investment security and compatibility across manufacturer boundaries. The PNO (Profibus User Organization) views the M12 with L-coding as a new standard power connector and thus as a replacement for 7/8" concepts. Consequently, the M12 takes an important step in the direction of modularisation and miniaturisation.

Yesterday’s light bulb is now the LED. For the connection of high-performance light-emitting diodes (LEDs), e.g. in street illumination, indoor and area lighting, as well as LED displays and emergency lighting, HARTING is now offering white PCB terminals and connectors with 2.54mm grid size in its har-flexicon® series. HARTING uses white plastic granules, which are characterised by high temperature resistance and long-lasting colour stability. In addition, white PCB terminals which are flat in design reduce disturbances caused by shadowing in light fixtures. The use of har-flexicon® for surface mount soldering significantly simplifies the manufacturing processes for lights. The SMD-capable terminals offer cost advantages in the manufacturing process of lights through the use of automated assembly and soldering processes. The product family offers 2- and 3-pole terminals with a white housing colour for flexible and rigid conductors with cross-sections up to 0.75 mm². With a nominal current carrying capacity of 6 A, the har-flexicon® offers users sufficient reserves when dimensioning lighting fixtures.

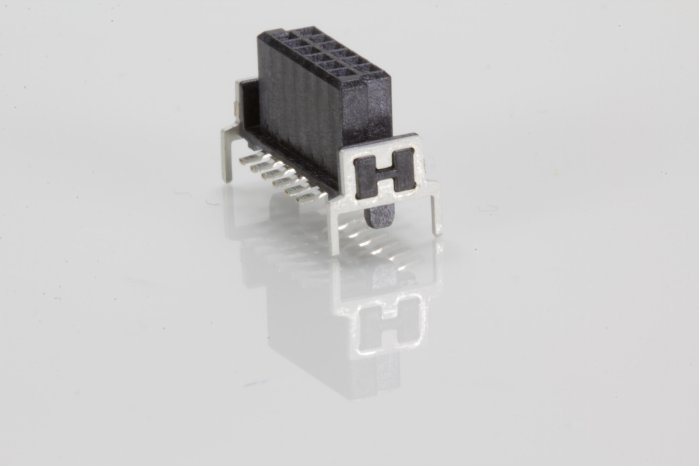

In the PCB connector field, HARTING will display another highlight in the form of its new har-flex® THR variants. THR stands for Through Hole Reflow and describes the termination technology featuring laterally attached binders. The 1.27mm pitch space connectors combine the mechanically stable soldered connections of the through hole technique with the advantages of automatic processing of SMD components. This makes the connectors ideal for miniaturised and demanding mechanical applications which previously required larger connectors.

In keeping with the industrial requirements of tomorrow, the M12 Slim Design family will also be presented. Here, particular attention is paid to small dimensions suitable for confined spaces, as well as Ethernet cabling in rail transport. With space-saving metal housings and pioneering performance for all three lifelines, the M12 Slim Design family provides solutions for demanding application environments.

"With these highlights, HARTING is keeping abreast of the miniaturisation trend which has been strengthened by Industrie 4.0, and is designing future interfaces for intelligent connectors", says Ralf Klein, Managing Director HARTING Electronics.