As a response to the challenging and increasing demand for global digitalisation technology, both partners – HIROSE and HARTING – agreed a few months ago to combine their strengths. The result of this joint effort is ix Industrial® – a new miniaturised Ethernet interface for high data rates. At the same time, the two partners have jointly standardised the ix Industrial® mating face in accordance with IEC/PAS 61076-3-124. This standardisation provides users with investment security and with a broadbased technology and always offers the right contact partner for future applications in IoT. The production is planned to start on April 2017.

"Together, HIROSE and HARTING will now be able to offer our customers the combined expertise of two leading interconnect technology companies, and their global presence with proximity to customer design and manufacturing locations," said HIROSE President Kazunori Ishii at a press conference at electronica. Speaking at the same event, Philip Harting, Chairman of the Board of the HARTING Technology Group, added: "Successful collaboration in developing, standardising and marketing the miniaturised connection technology for 10Gbit Ethernet is a genuine win-win situation for both companies. We want to extend this partnership further."

In particular, HIROSE and HARTING want to work even more closely on research and development in the future. More standards are also planned be set.

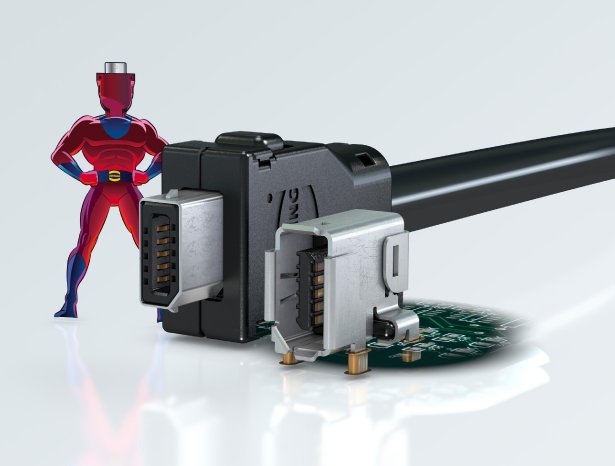

Consistent miniaturisation and more robust construction

While the ix Industrial® has been developed jointly with HIROSE, HARTING has created the T1 and the M8 alone. The mission is clear for all these three superheroes: ix Industrial® and its two comrades T1 (“Tw1ster”) and M8 (“Miss M8ty”) are campaigning for better performance in industrial data traffic. They are all smaller, more robust and more powerful than comparable connectors. Due to this small and robust design, they make fast Ethernet available to every conceivable application. The ix sockets are 70% smaller than those of the established RJ45.

This means that device manufacturers can use them in much smaller devices, allowing them to comply with the constraints of miniaturisation. Such devices might be the ever shrinking camera systems in which the traditional RJ45 socket occupies most of the space in the housing, or control units and small industrial computers. The socket has 5 THR shielding contacts for maximum stability on the PCB. Developers and manufacturers can easily integrate the new ix Industrial® system in new devices and also have the assurance that this interface is firmly attached to the PCB and will withstand rough handling.

Customers require less space for connection technology

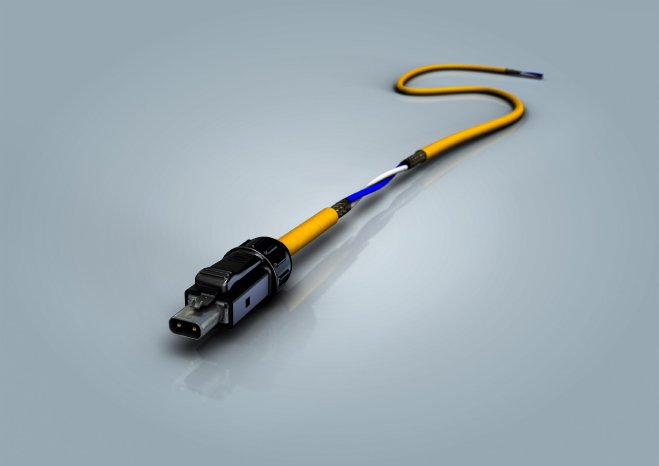

For device cabling, HARTING offers users thin, flexible system cables with a small bending radius which also facilitates installation in miniaturised housing. There is a version with the ix mating face on both sides and an ix and RJ45 connector combination. The third variant has an X-coded M12 on one side.

As a general rule, small is seen to equate to delicate, but also to fragile. However, since precisely these unfavourable properties in the RJ45 have frequently caused problems in industrial environments, the ix Industrial® socket and connector are both designed to be significantly more robust. ix connectors are secured firmly with two metal hooks which can be heard to click into place, providing users with audible and tangible feedback that the connection from the cable to the PCB has been made correctly and is guaranteed to be absolutely secure and free of vibration.

With performance in Cat. 6A, the ix Industrial® mating face is configured for 1 / 10 Gbit/s Ethernet and therefore future-proof. High current load capacity accommodates the PoE applications of today and tomorrow. It therefore combines data transmission and power supply in one interface. Customers require less space for their connection technology.

T1 is the hero for single-pair GBit Ethernet

So that the ix hero does not have to improve performance on its own, it has the T1 (HARTING T1 Industrial®) in support which represents current technological development in the area of single-pair Gbit Ethernet. At both of the autumn trade shows, "electronica" and “SPS IPC Drives”, HARTING will present a live demonstration system which will allow visitors and customers to see 10GBit transmission via a twisted pair cable. This pioneering approach saves space, costs and cabling work and is of interest particularly to very small Ethernet users. The HARTING Technology Group is currently working on standardising an appropriate mating face as part of an IEC norm project.

M8 is the specialist for Ethernet, Cloud and field cabling

Elegant with its space-saving curved shape, the HARTING M8 is the third member of this strong and fast trio. It is synonymous with the lean transmission of Ethernet from the Cloud to the most remote field cabling. It means that control and monitoring are no longer isolated systems, but can communicate globally with other locations and with the sources of information required. ix Industrial®, T1 and M8 d-coded – three heroes standing for a new generation of small and robust connectors for better performance in the industries of tomorrow.

You find the press information also here: http://www.HARTING.com/en/news/pressfolder/sps-electronica