The HAVER & BOECKER ROTO-PACKER® ADMAS MINI reaches speeds of up to 600 bags/hr at steplessly selectable weights of 1 - 10 kg. Today filling into bags made from a tubular film or into every type of pre-manufactured bag is possible. And by using an additional module, the bags can be formed directly from a flat film within the ROTO-PACKER® system.

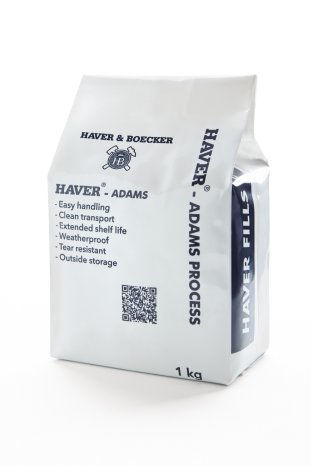

The bags are closed airtight and are weather-resistant, clean and compact. Moreover they provide for perfect appearance. Also from a marketing standpoint PE bags offer additional advantages in that they allow for full-surface, multiple-colour print and photo-quality images, product information and barcodes. With this high quality packaging, customers increase the value of the product's image and can present it standing up on store shelves. Customers save on packaging and stocking costs, and have fewer customer complaints.

"The market had recognized the general advantages of filling into PE bags and made positive experiences. So about one year ago we got the request to expand the technology so that it would also handle the typical package sizes of 1, 5 or 10 kilograms," recalls Burkhard Reploh, Manager of the Building Materials and Minerals business unit. Since then the specialists at HAVER & BOECKER have been busy expanding the filling weight range.

Product compaction plays an important role during filling. Depending on the product, not only the proven techniques such as the vibrating bottle are used with the ROTO-PACKER® ADAMS MINI, but also new methods. "Our concept for success is the removal of air at and in the bag," explains Reploh. The technology will be ready for the market by the end of the year. Meanwhile the experts at HAVER's Innovation Management are already concentrating on increasing the speed to 1200 bags/hour.

www.haverboecker.com