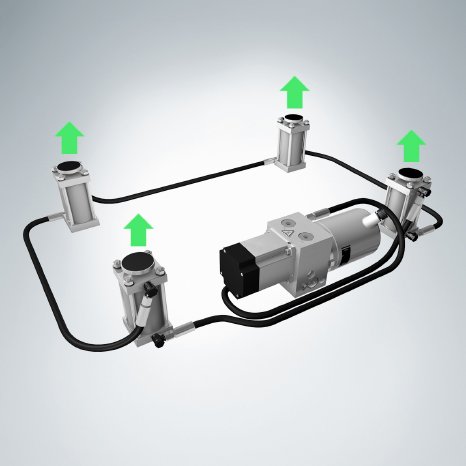

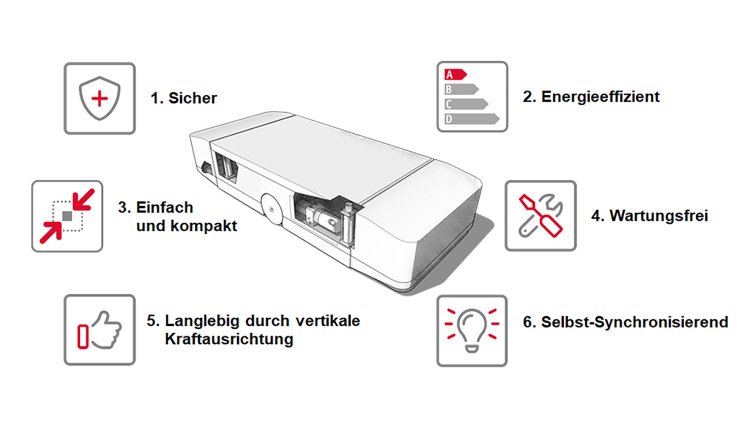

The patented new development ensures precise synchronization and self-synchronization thanks to the series connection of the four differential cylinders – time-consuming programming for synchronization is no longer necessary. Supplied ready for connection, users do not require any hydraulic knowledge for installation and commissioning, which operators can simply implement via plug & play.

Less wear and high efficiency

Compared to electromechanical applications, LOGAR applies 100% of the forces vertically from the start of the stroke. This completely avoids lateral forces and reduces wear. “Our customers benefit above all from 1,000,000 maintenance-free cycles. This is because LOGAR has a three times longer service life compared to electromechanical solutions,” says Ahmed Wasel, Key Market Manager at HAWE Hydraulik.

In addition, the efficiency of the integrated BLDC motor is higher than that of brushed motors, achieving 85% to 90% efficiency. Its pilot-controlled non-return valves hold loads of up to 1,500 kg securely in position and prevent unwanted lowering. The lifting and lowering process can be switched quickly, directly and without loss, by the user changing the direction of rotation of the pump-motor unit. LOGAR is also leak-free: the enclosed design prevents the ingress of impurities and the escape of oil, which further increases safety during operation.

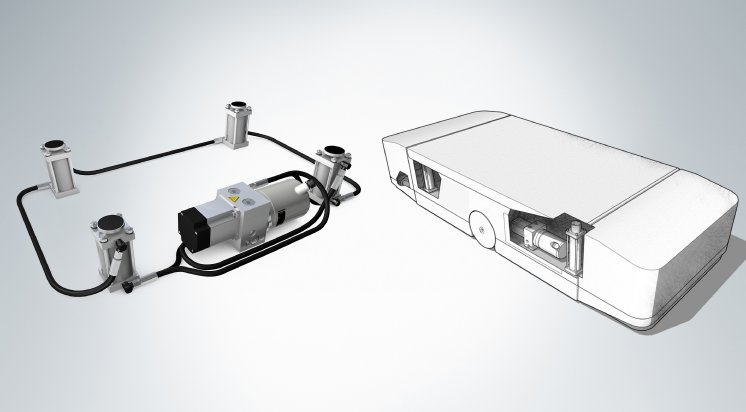

Compact design

With its compact design, LOGAR creates space for the installation of additional components. Thanks to a proven modular system and systems engineering expertise, HAWE is able to customize the solution to the requirements of the AGV and AMR platforms. “This means that our new development even exceeds some of the key requirements that are placed on AGV and AMR platforms,” emphasizes Wasel. From March 11 to 13, 2025, the hydraulics specialist will be presenting the LOGAR system at LogiMAT in Stuttgart in Hall 10, Stand A 45.

More information at: www.hawe.com