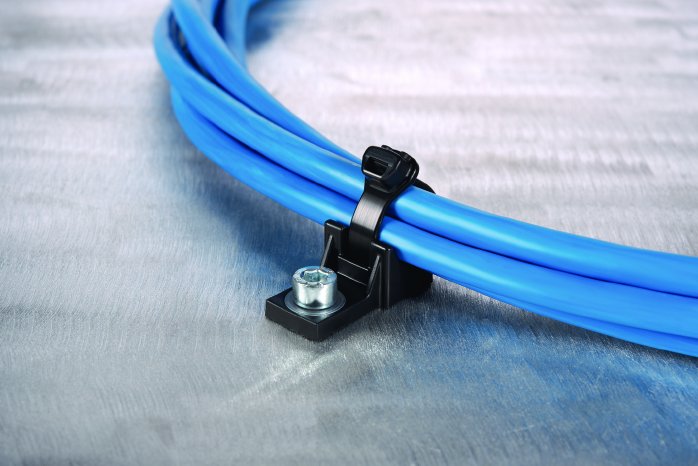

X-Series cable ties now offer a space-saving solution that meets the high fastening and fixing demands of mechanical and vehicle engineers.

Its slim, rounded head geometry makes the X-Series an ideal choice in scenarios where space for fastening cables and wires is limited and smaller cable ties do not deliver sufficient holding force.

“The special X-Series head shape allowed us to reduce the height from the bundle”, said Jan Göllner, responsible product manager at HellermannTyton. “The rounded head geometry lets the X-Series lie closer to the cable bundle than a standard cable tie and adheres securely without any side-slippage.”

Small changes in the design mean that the tie band runs optimally into the head. The low insertion force and the use of ergonomic manual cable tie application tools, such as the HellermannTyton EVO range*, make child’s play out of bundling in confined spaces.

X-Series cable ties are available directly to order from HellermannTyton in UV-resistant (PA66W) and high impact modified, heat stabilised (PA66HIRHS).

* The HellermannTyton EVO7 and EVO9 manual application tools for plastic cable ties include patent-pending TLC technology (Tension/Lock/Cut), which significantly reduces the physical strain on operators. When the selected tension setting is reached, the locking mechanism holds the tie firmly in place before it is cut. Locking the tensioned cable tie band almost entirely removes any “kickback” when it is cut flush. Further information: EVO9 press release