In order to further improve the complex, fine-tuned interaction between the dosing machine and the linear robot, several modifications were performed to the SMART - DM 402 dispensing cell.

The mixing and dosing area as well as the linear robot are compactly located on a common base frame of the dispensing cell. Thanks to standardised individual modules, the SMART dispensing cell has a simple and modular design. It has large, rectangular openings close to the lift gates at the front and on the sides as well as inspection windows which can be inserted individually. Thanks to the modularity of the SMART dispensing cell, subsequent modifications due to changed production concepts can be realised quickly and with less planning effort. When it comes to frequently changing applications and part quantities, different modules can easily be attached to the cell body. Unobstructed access to the dispensing cell for maintenance and cleaning purposes is ensured by opening the maintenance door at an angle of 180° over the full height. If, for example, the rinsing containers below the mixing and dosing level must be emptied, this can be done in a user-friendly manner by means of a telescopic drawer.

Easy access to the dispensing cell is also given by the removable cell roof. Without the roof, depending on the adjustable setting of the mounting feet, the cell has a height of 2.20 m. This is of particular importance for ocean transports in maritime containers where the door opening has a height of 2.28 m according to ISO standard.

High user friendliness of the SMART - DM 402 dispensing cell

A better ease of use is achieved by improved accessibility to the mixing and dosing area in the cell. The lockable enclosed machine cabinet with the peripheral system devices is directly located at the rear wall of the cell. The controllers are still located in a separate control cabinet. A separate supply level in the cell floor ensures a protected guidance of the electric and pneumatic lines. The hose guide of the individual material components from the dosing pumps to the mixing head has also been improved.

The machine operator has enough space in front of the dispensing cell in order to easily insert the part. Feeding the dispensing cell with parts for applying foam gaskets, glues or potting compounds is done in a user-friendly manner by means of an automatic rotary indexing table with a 180° partitioning for an insertion and a work position which change within 1.5 seconds. Access to the insertion area on the rotary indexing table at the cell is secured by a light grid.

As an alternative to the rotary indexing table, there is a version where the parts are directly inserted on a worktop into the cell. In this case, a lift gate is attached to the front of the cell. It is also possible to feed the parts via a transfer belt running through the cell.

Fast responsiveness thanks to the built-in safety technology

The new SMART - DM 402 dispensing cell presented at the Fakuma trade fair also gives high priority to occupational health and safety. By using the latest built-in B&R safety logic instead of the previous safety technology with discrete components, safety functions such as light grids, safety door switches or safety shut-off mats and even more complex safety functions such as SLS (Safety Limited Speed) can be realised.

The control processes may be flexibly programmed depending on the respective part application and production concept. In addition, the new safety technology requires less space in the control cabinet of the SMART - DM 402. Conventional electrical safety circuits were previously implemented with electromechanical safety switching devices which are less flexible due to their hard-wired functions. By means of programmable safety logic, the safety functions may be adapted much easier and faster.

The SMART dispensing cell is equipped with a new servo technology that makes use of the most recent B&R servo controllers. Individual double or single controllers are simply attached to a base module which means that the attached modules can be easily replaced for service purposes. The power is supplied via a central module by means of which the communication of the control is handled - that allows for easy wiring in the control cabinet.

The safety functions of the servo-controlled axes of the linear robot and the rotary indexing table are fully integrated in the programmable safety logic and may therefore quickly respond to safety events. The transmitters of the new servomotor series are now digital instead of analogue and have a better resolution which results in a higher axial stiffness and thus in better path characteristics of the axes when moving the mixing head.

Using an electronic nameplate in the servomotor provides the advantage of an automatic parametrisation of the controller to the current parameters of the connected motor.

Referencing the positioning axes of the linear robot of the SMART dispensing cell is no longer required thanks to the absolute value transmitters used. This provides the advantage that the axes may immediately be operated following the start-up of the control without the need to move them to the limit switch in order to find the zero point.

Live presentation of the new SMART - DM 402 dispensing cell

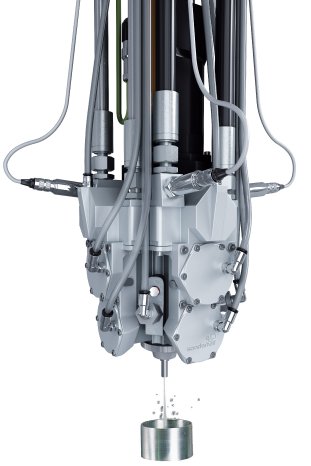

The triaxial linear robot of the Sonderhoff SMART - DM 402 dispensing cell can traverse industrial parts within a traversing range of up to 500 x 500 mm (width x depth) and up to a part height of 200 mm (max). The mixing head is positioned above the part with a repeating accuracy of +/- 0.1 mm thus ensuring a reproducible sealing, gluing or potting result.

There will be a live presentation by Sonderhoff of the SMART - DM 402 dispensing cell in hall A5, booth no. 5109. Professional visitors can inform themselves on the high ease of use and the new safety standard of the dispensing cell as well as on the advantages of the integrated digitalisation of the control technology.