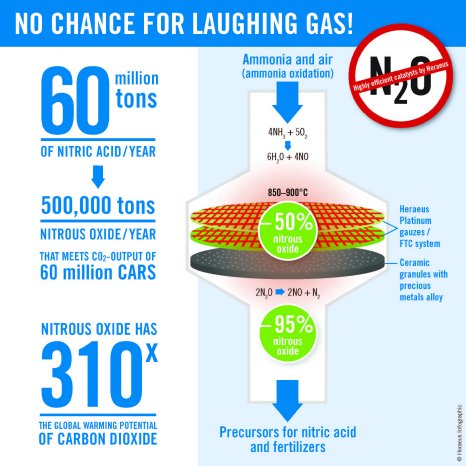

When basic chemicals for fertilizers, such as nitric acid, are produced, the process releases nitrous oxide into the atmosphere as a byproduct. This greenhouse gas has 310 times the global warming potential of carbon dioxide (according to the Kyoto Protocol, based on 100 years) and is thereby a major factor in global warming. More than 60 million tons of nitric acid are produced around the world annually, with an estimated 500,000 tons of nitrous oxide generated as a byproduct – equivalent to the carbon dioxide emissions from over 60 million mid-sized cars.

Climate protection starts with nitric acid production

Nitric acid is produced as a basic component in nitrate fertilizers using a process called ammonia oxidation (Ostwald process). Ammonia and air are routed over platinum gauzes heated to 900°C, producing nitrogen oxide that bonds with water to create nitric acid. This chemical reaction requires up to six meters of round gauzes made from platinum alloys. Heraeus has been a leading producer of these precious metal catalysts worldwide for more than 100 years. During the ammonia oxidation process, nitrous oxide emerges in a secondary reaction. Heraeus’ patented FTC1 gauze systems are already reducing nitrous oxide emissions by up to 50%. However, a special catalyst system installed downstream can further reduce emissions by up to 95%. Heraeus offers these precious and non-precious metal catalysts to achieve these reductions. “Precious metal catalysts offer immense benefits when retrofitting plants. For example, they require less space, are highly efficient and have longer service lives. The catalyst is installed in the nitric acid reactors directly below the existing catalytic gauzes,” explains Eckert. The nitrous oxide molecules pass through the granulate-like catalyst and are, with a few exceptions, destroyed – turning into nitrogen and hydrogen.

Customized full service retrofitting worldwide by Heraeus

The system can be adapted to specific customer requirements and allows existing reactors to be retrofitted at a reasonable cost. Heraeus has been installing this innovative system solution into existing nitric acid plants since 2006. “Plant operators benefit from our full service as a solution provider. Technical service teams for customers in America, Europe, Africa and Asia are available to customize this gauze and catalyst system solution, install it on site and check the process parameters while in operation,” explains Jörg Eckert.

The demand for retrofitting nitric acid plants will certainly rise with the increasingly tougher legal requirements for reducing nitrous oxide emissions in the coming years. By 2020, the target year set by the Nitric Acid Climate Action Group, all nitric acid plants should be equipped with nitrous oxide reduction technology. Developing countries, in which the relevant technologies are often not yet available, will benefit particularly from this initiative. The Heraeus catalyst system thus offers a suitable, well-established system solution for reducing nitrous oxide emissions to under emission limits. This means the world may soon be able to breathe a bit easier.