Production for Germany's first quartz glass manufacturer originally took place in Griesheim near Frankfurt. "The oxygen and hydrogen gases required to melt the glass could be obtained directly from the Griesheim- Elektron company. Founding the new enterprise was Heraeus' response to an increasing demand for quartz glass and its products; it also brought together innovative technologies," says Heinz Fabian, the business group's Managing Director. Today the company operates locations around the world-in Germany (Hanau, Kleinostheim, Bitterfeld), the United States (Austin, Buford, Wilmington), China (Shenyang), and England (Wallsend)- and has over 1,400 employees. Heraeus is one of very few specialists with expertise in this material, providing a level of quality in its standard production processes that is unique the world over.

Quartz glass is the key to the information age

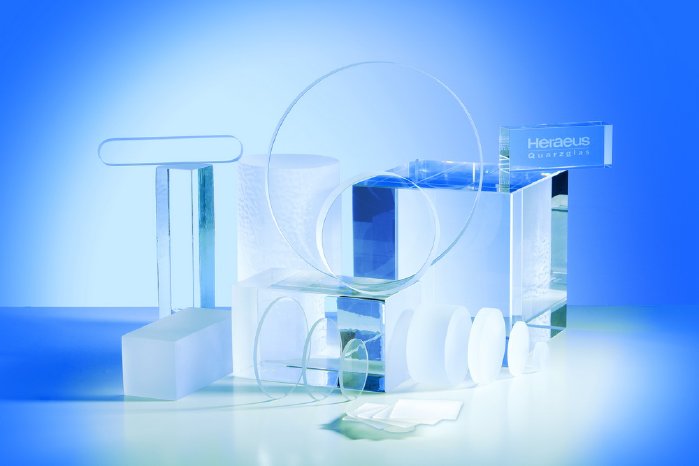

Heraeus Quarzglas GmbH first produced laboratory equipment made of quartz glass for the chemical industry. This was followed by other uses, such as optics (optical quartz glass), temperature measurement (platinum resistance thermometer), and lamps (such as the original Hanau Höhensonne® sun lamp). Thanks to its high quality, over the course of the 1950s, optical quartz glass from Heraeus conquered challenging new areas of application in the fields of astrophysics, aerospace engineering, microelectronics, optical telecommunications, and the semiconductor industry. In 1955, the company produced synthetic fused silica for the first time. Using special blowpipe technology, ultrapure quartz glass with a high degree of UV transparency was produced. Under the brand name Suprasil®, it was embraced by aerospace engineering for use as mirror prisms and lens and window material.

Today, high-purity silica glass is indispensable for the production of microchips and solar cells. "Without quartz glass, there would be no internet. It is the key to the information age, so to speak," stressed Wolfgang Stang, likewise Managing Director of Heraeus Quarzglas. Optical fibers as thin as a hair transmit huge amounts of data quickly and securely over continents and under oceans. Heraeus manufactures synthetic quartz glass tubes and cylinders at locations in Buford, USA and Bitterfeld, Germany. These products have been used to produce more than 300 million kilometers of glass fiber for optical data transmission technology to date.

High tech in Bitterfeld and on the moon

Synthetic fused silica from Bitterfeld, Germany, is now used worldwide in the telecommunications industry. After the fall of the Berlin wall, in the early 1990s, Heraeus was one of the first investors in the industrial area and new chemical industry park in Bitterfeld. The foundation stone was laid for the site over 20 years ago. Mass production of synthetic quartz glass hollow cylinders began after the launch of operations in 1992. The number of employees at the plant continues to increase, along with the size, weight, and quality of the silica bodies manufactured there. Today, up to 7000 km of fiber can be drawn from a 3-meter long preform.

The quartz glass experts are also proud of the fact that Heraeus is one of the few companies immortalized on the moon. In addition to putting the first man on the moon on July 20, 1969, the legendary Apollo 11 mission also carried a laser reflector to Earth's natural satellite. Still in operation today, the reflector is used to measure the exact distance between Earth and the moon (about 384,000 km). It consists of an array of 100 triple prisms made of quartz glass from Heraeus.

Background: quartz glass is different

Although extremely difficult to differentiate from normal glass, quartz glass (SiO2) possesses other significant properties such as chemical and temperature stability, resistance to radiation and optical transparency. Synthetic quartz glass is considered one of the purest materials. It contains trace elements in very small concentrations, often only in the ppb range (parts per billion). Quartz glass is so pure that you could see through a 100 m thick slab of it as if it were a piece of thin window glass. The material possesses high optical transmission in the ultraviolet to infrared spectrums, as well as being resistant to thermal shock. That is, it can be heated and cooled very rapidly without shattering as normal glass would.

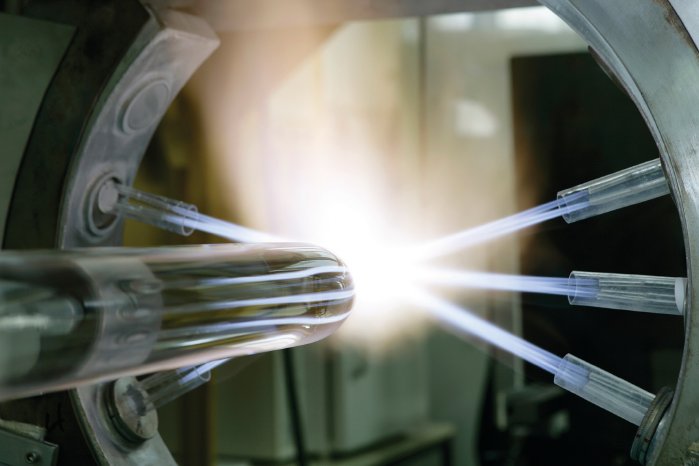

Considering its fascinating nature, it is astonishing that so few universities and research institutes work intensively with the properties and applications for quartz glass. For that reason, most expertise is generated in the private industry sector. Generations of Heraeus researchers have made great contributions to our understanding of this exceptional material. Quartz glass activities at Heraeus go back more than 113 years. In 1899, physicist and chemist Dr. Richard Küch (1860-1915) melted rock crystal at 2000°C using oxyhydrogen blowpipe technology (oxygen-hydrogen flame). This gave him virtually bubble-free quartz glass, which was first used in the optical industry to manufacture optical lenses and then to produce specialty light sources, such as the original Hanau Höhensonne sun lamp.