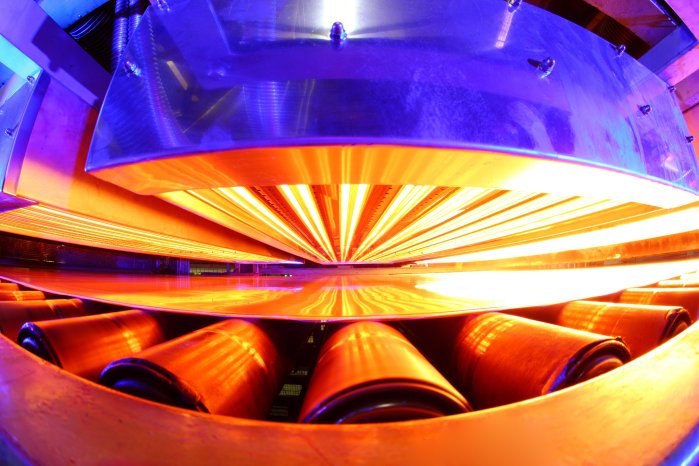

Multi-layer plastic foils are used for the hygienic packaging of foodstuffs. To join the layers together, the foils are heated and then joined by means of calenders. Heavy duty plastic floor products often have a decorative embossing. To achieve a high quality result, after a pre-heating, the surface is then directly heated again shortly before the embossing station. Whether laminating or embossing, the large surface must always be heated homogenously and, hence, it is important that the correct heat source is selected.

Carbon infrared emitters improve the quality of floor coverings

Polyflor, of England, manufactures heavy duty floor coverings for use in schools, hospitals and commercial organizations, throughout the world. In the manufacture of floor coverings in Manchester, a 2m wide PVC (polyvinyl chloride) web is heated by infrared emitters before being embossed with decorative patterns. Short wave infrared emitters had previously been used for this application but they did not heat all colors optimally and geometric integrity was often affected during embossing. In order to solve the problem, intensive tests were carried out in the Heraeus Application Centre, and as a result, a medium wave carbon infrared system was installed. Short wave infrared radiation penetrates deeply into thick plastic materials, while medium wave carbon infrared emitters can heat the surface better. Tests can demonstrate which radiation is best for specific tasks. Neil Holden of Polyflor is convinced of the benefits of the infrared system, "The new system has ensured that embossing no longer affects floor covering geometry. We were very impressed with the tests carried out at the Heraeus Application Centre and with the way that the system was installed with minimum interruption to the production process."

Process Improvement by Exact Matching

Infrared heating technology offers various possibilities to optimize industrial processes:

- High heat transfer capacity

- Contact-free heat transfer

- High efficiency

- Efficient energy transfer by selecting optimum wavelengths

- Spatially focused application of energy by matching the heating to the product shape

- Fast response times to reduce energy consumption

Consequently, infrared heat is always used when heat processes are to be implemented which require particular targets in terms of space, time or quality.