“Size reducing, washing, separating and drying, and agglomeration are our main processes. Our customers value our wide range of machine options and the ability to obtain custom plant designs from a single source. With our focus on the circular economy, we are fully in line with the current spirit of the times and with one of the main topics of the K 2019 trade fair”, says Werner Herbold, one of the two general managers.

1. Pre-shredding

Pre-shredding is an essential process step when the feed material is too bulky to process or when it has to be coarsely broken up before sorting, visual inspection, or testing. We use shredders, granulators, guillotines, and hammer mills for pre-crushing. For example:

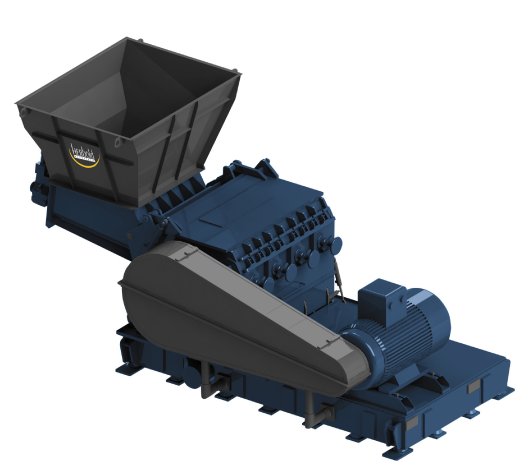

The New EWS 60/210 Shredder:

The demand for high-performance shredders that can process entire bales is increasing, especially when used in washing lines. Herbold will present the EWS 60/210 for the first time at the K 2019 trade fair. This shredder was developed for dry operation as well as for wet operation and will impress you with its maintenance-friendly design in addition to its high capacity. The machine is designed to be very robust and durable. In many plants, the crusher is the first stage in the process. In this stage, foreign bodies are often impossible to avoid. For this reason, we have taken some of the special features of this stage into account during its development that cannot be found in any other machines on the market. “We focus on making a perfect wear-protected rotor that, in addition to custom knife configurations, is equipped in particular with bolted armor plating and a special grinding chamber seal”, stated Daniel Zeiler, Head of Sales.

The time-consuming hardfacing of rotors is therefore unnecessary.

The two-sided belt drive is low-maintenance, and to safeguard against foreign bodies, there is a clutch that prevents damage to the machine when uncrushable feed material is encountered.

The maintenance concept is tailored to ensure optimal accessibility based on ergonomic considerations.

The first machines are already successfully in use at customers in Europe, and the official product launch will take place at the K 2019 trade fair.

The new DWS two-shaft shredder

A new two-shaft shredder with the stator positioned in the middle will be presented as a new innovation at the fair. Due to the large surface area of the rotor, the machine has a very good feed performance and is suitable for materials that can only be fed in doses using conventional shredders such as big bags or high-volume containers.

2. Size reduction

Herbold granulators grind all plastic waste materials, regardless of whether it’s generated from injection molding, blow molding, deep drawing, rotomolding, flat sheet or blown film extrusion, and calendering processes or waste generated during the manufacture of pipes, profiles, sheets, or other plastic products. For example:

SB granulators with force feeding

The Herbold SB series granulators with force feeding have been used successfully worldwide for many years. “We have consciously redesigned this series of machines to enable complete horizontal charging”, stated Karlheinz Herbold, who is responsible for the technology as the Executive Director. The feed material is not fed into the grinding chamber from the top through the force of gravity as in the case of standard granulators, but by even feeding the material into the grinding chamber horizontally at the height of the rotor using screw conveyors. To accomplish this, the machine housing and feed system were completely redesigned to meet all requirements in terms of size-reduction performance as well as ease of access for maintenance purposes.

When dealing with difficult applications, there are only a few providers on the market for size reduction technology who are able to offer an appropriate machine. The key to the solution is the rotor design of the SMS granulator.

The rotor, which is manufactured from a single forged piece, guarantees stability. Welding seams cannot break because they do not exist. The knives of this rotor cannot shift because they are bolted to a massive backstop. This design also makes cleaning easier since there are no “dead spots” in which grinding residue can deposit.

3. Washing, separating, and drying

In recent years, Herbold has invested a lot in the area of washing lines. In addition to our own technical department, we have assembled a motivated team of process technicians and project engineers. We are therefore able now to offer our customers complete high-performance solutions. The success of a design that operates well is only based in part on the machines. The treatment of process water also plays a decisive role, especially for washing lines. Herbold also offers solutions covering this area as well now.

We focus on providing our customers with comprehensive consulting, stated Achim Ebel – Division Manager for washing lines. For this reason, we look closely at the planned input quantities and compositions, but at the same time keep an eye on the desired applications for the washed end products. We do not offer washing lines off the shelf – designing a solution that meets the particular requirements is a more intensive individual process performed together with the customer.

We seek close contact to our customers, talk openly with them about our experiences, and allow the results to flow into development. For this reason, numerous developments are from practical applications and for practical applications, and our systems are always improving and becoming more efficient. Due to this agility, our customers always receive designs that are the state of the art in technology.

Herbold offers tried and tested solutions for the following applications in particular:

- Post-industrial and post-consumer films

- Post-consumer hard plastics

- PET bottles

- PET trays

- Big bags and other monofilaments

- Tetra packs and pulp waste

VWE 700 prewashing unit:

An important component in a Herbold film washing line is the multistage prewashing unit, which captures coarse foreign bodies and reduces the mineral fraction, both to protect the subsequent machines. The remainder is also gently prewashed. The type of prewashing developed by Herbold Meckesheim has been a proven technology for a long time already that has convinced our customers.

We have now optimized this process step even further by increasing the throughput performance for films, optimizing the flow of water, and integrating a baffle plate thickener into the unit to clean the process water. We therefore remove contaminants directly on the unit.

Hot washing:

Increasing quality requirements in the plastic recycling industry also require optimized cleaning stages when building a plastics recycling plant. An important step in plastics recycling is the hot washing step, which has been a major step in the PET bottle recycling process. Herbold Meckesheim has advanced this step of the process for PO films and can offer optimized temperatures and appropriate dwell times, and can provide optimal cleaning results and end material quality through the use of suitable additives.

Mechanical drying

The dryers from Herbold Meckesheim already meet the highest quality requirements in terms of higher drying efficiency and performance, better accessibility, wear-protected parts, and automatic cleaning systems. Nowadays, we have also implemented the principles of multistage vertical drying in our horizontal dryers. This improves the product output rate and the lifespans of the wear parts.

Furthermore, the thermal drying process was optimized.

Thermal drying

The two-stage thermal dryer is completely new. The flow through the coils was optimized and the heating temperature was improved in terms of energy consumption. This design is used especially in the recycling of increasingly thinner films. It is used to reach low residual moisture contents and ensure the material can be processed afterwards with as little energy as possible.

Label remover

Herbold has made numerous minor improvements, and therefore introduced a new and improved generation to the market. Based on a proven basic principle, the HERBOLD HLR label removers are now much more variable. This applies to the removal process as well as to the integrated separation using a classifier. We are now able to control the dwell times and intensities of the label removal process much better. To accomplish this, we use a series of adjustable machine parameters. Our experience has shown that it is essential to trim the machine to match the input material. Maintenance and readjustment of the tools is also much easier now.