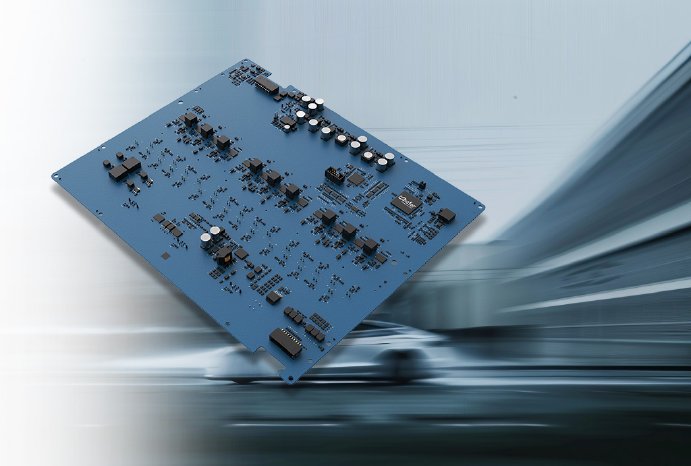

The ONEboard+ is a crucial component integrated into an inverter, determining its functionality. This important element seamlessly combines hardware and software, providing a comprehensive solution for the complex control requirements of the most advanced electric vehicles of all kinds.

Based on the success of the original ONEboard, the ONEboard+ enables significant cost savings for an inverter. These savings are particularly noticeable for OEMs at the vehicle level. In addition to the basic inverter function, the significantly increased computing power allows for the integration of additional functions such as an on-board charger or a second inverter in a single layout. The new solution also plays a crucial role in the implementation of torque vectoring. The new generation of this Control Board supports future-proof functionalities, including 3-level inverter solutions, to maximize performance and efficiency. Compliance with the latest cybersecurity standards is ensured through the use of the latest microcontroller technology.

Johann Paul Hofer, CEO of hofer powertrain, emphasized the universal application capability of the ONEboard+. "The truly unique feature of this Control Board is its adaptability. Regardless of the type of motor—whether ASM, PSM, or even EESM—customers can rely on the same platform. A high level of standardization simplifies manufacturing processes and significantly reduces costs."

“Our continuous development efforts ensure that the ONEboard+ remains among the most advanced control systems for powertrain solutions. With updates in chip technology utilizing the latest microcontrollers and peripheral chips, we are expanding its capabilities to support future electric powertrains. This not only brings cost savings to our customers but also minimizes their time-to-market, using our solution,” adds Thomas Roubal, Hardware Project Manager at hofer powertrain in Germany.

The ONEboard+ now supports up to three independent CAN nodes. The gate driver features an adaptive slew rate, which can reduce switching losses by up to 25%. Additionally, the BOM costs can be significantly reduced compared to the previous solution by incorporating the electrical drive for EESM as an integrated solution rather than a separate component. Furthermore, the ONEboard+ supports both 12V and 24V electrical systems, making it suitable for commercial vehicles as well. The goal in projects is to meet the ASIL D requirements for functional safety with the ONEboard+. With over 40 years of experience in developing complete drive systems, hofer powertrain also realizes complete inverter solutions based on the ONEboard+ for both 400V and 800V HV electrical systems, achieving peak power outputs of more than 500 kW. The high scalability of the ONEboard+ makes it easily adaptable to meet the diverse requirements of OEMs.

As hofer powertrain continues to refine and improve the ONEboard+ solution, the company remains focused on delivering top-quality products that meet the evolving demands of the automotive industry. Through a structured development process and an attractive licensing strategy, hofer powertrain offers its customers an efficient and cost-effective way to integrate state-of-the-art electronic solutions into their powertrain systems.