Refinery FCC is at the heart of any modern refinery as a pivotal petrochemical process that converts hydrocarbon fractions from petroleum (crude oil) into valuable products such as olefinic gases, gasoline, and other important petroleum products. Transitioning toward the co-processing of biogenic feedstocks provides refiners with an attractive and viable option for contributing to global decarbonization efforts to reach climate goals and for complying with ever more stringent regulations. The European Commission, in particular the JRCs (Joint Research Centers), have a great interest in identifying a verifiable alternative methodology to Carbon14 radiocarbon analyses for allocating the bio-based content in liquid or gaseous products and fuels from co-processing bio-oil in a refinery. This is because preliminary investigations rule out radiocarbon analysis as not being sufficiently sensitive to reliably determine the biogenic carbon content at low levels.

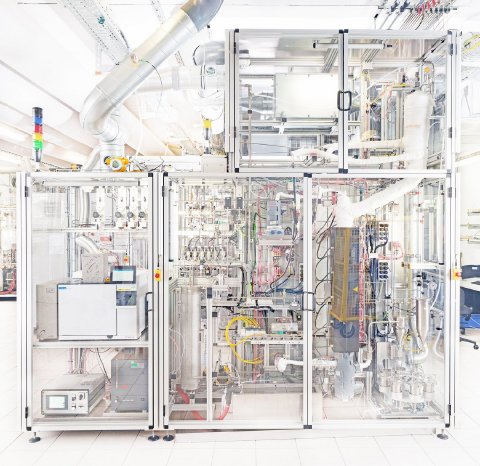

Under this research contract and with the support of key stakeholders from the oil and gas industry, hte has developed a methodology using its proprietary Micro Downflow Unit (MDU). The unit is a laboratory-scale FCC plant and is employed as flexible pilot-testing and production equipment to generate data to determine the distribution of biogenic carbon content in FCC FPBO co-processing via total mass, carbon mass, and energy balancing as well as delta yield methods. For this purpose, hte’s MDU was equipped with a dual-pump setup for co-processing of 0, 5, and 10 wt.% FPBO with traditional vacuum gas oil (VGO), as these types of feeds are not miscible. Additionally, the project included collecting comprehensive physical and chemical data on the feeds and all gaseous, liquid, and solid product fractions to support the different balancing methods, including bio-based carbon determination via EN 16640 (Carbon14 AMS detection) of the various products for comparison.

“We are excited about and proud of the contribution our technology is making to the potential development of a new standard to allocate biogenic carbon content in the refining industry”, comments Wolfram Stichert, CEO at hte. “Over the years the MDU has proven to be a valuable FCC laboratory-scale testing technology for catalyst benchmarking, yield predictions, and the co-processing of biogenic feedstocks, to name a few applications. We are confident that this versatile technology and the methodology developed will play a significant role in assisting refiners in overcoming the daunting challenges of decarbonization.”