The precise evaluation of camera images in fluorescence applications is a major challenge, due to the physical conditions of UV light. UV lights are generally used to make invisible features on products visible. The UV radiation causes certain materials to glow. This glowing is clearly visible to the human eye and to cameras. The great challenge with fluorescence applications in industrial image processing is, that the emitted light (fluorescence) has less energy than the radiation required for stimulation. Fluorescence can be clearly identified by the human eye, while the UV radiation of the lighting is hardly perceived. A camera is however much more sensitive in the ultraviolet spectrum. The UV light outshines the fluorescence of the stimulated material in the camera image. The contrast is too low for a reliable evaluation. The LUMIMAX® team has developed a perfect solution for this field of application. A UV application can be optimised and reliably implemented by precisely coordinating lighting and lens filters. These allow the exact separation of stimulation and emission wavelengths. Interfering UV reflections and extraneous light influences are suppressed. As a result, fluorescent features appear brightly illuminated in the test image.

Visitors of the fair AUTOMATICA are cordially invited to be convinced of the effectivity of this solution at iiM AG’s booth 114 in Hall B5.

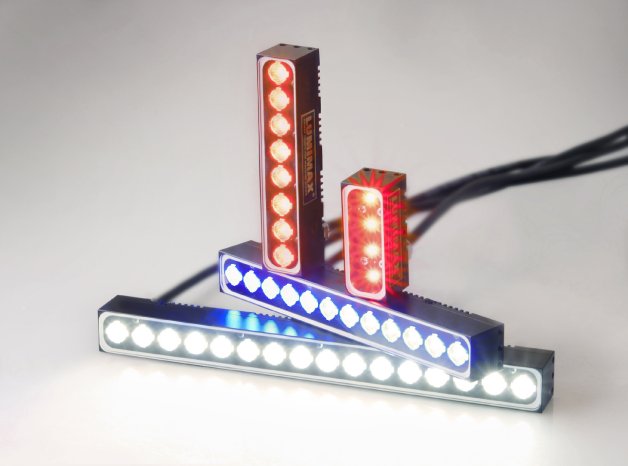

Another challenge of machine vision is to integrate optical processing systems in the given machinery. In compact designed systems with small construction areas, space-saving machine vision components are required. Therefore,iiM AG has supplemented the LUMIMAX® product range with powerful mini lights. These are extremely compact and can be easily integrated into the respective machine environment. Due to the use of high-power LED's, the mini lights are extremely bright, so that e.g. an irradiation intensity of about 130W / m² is achieved at a working distance of 100 mm. The mini lights include an integrated lighting controller and are available in the colours blue, green, red, white and infrared. Further advantages are both a separate switch input, which allows a load-free switching of the lighting as well as an M8 coupling, which also ensures a simple electrical commissioning.

The mini bar lights are available in four different sizes - from 50 to 200 mm. Its robust and anodized aluminum housing guarantees IP67. Thus, an integration in rough industrial conditions is possible. Just like the large bar lights, the mini lights also have a lens exchange option. This ensures an optimal adjustment of the light guide to the various inspection tasks.For an easy integration of the lighting into the machine environment, iiM AG provides a suitable mechanical mounting bracket. With this it is possible to align up to four lights as a square. This constellation is, e. g. excellent for the standard-compliant verification of DMC codes. Also, the Mounting bracket system enables a stepwise light direction adjustment from Bright – to Dark Field.

Besides the mini bar lights, iiM AG will be presenting the extremely compact and lightweight ring light LSR24. The feature of this mini ring light is that it can be directly mounted onto a lens filter thread. Overall, with the new mini lights it is possible to guarantee a fast, safe and especially space-saving integration into the machine environment. A wide range of accessories, such as a dark field attachment and various lenses, allow flexible adaptation of the lighting to meet your requirements.

iiM AG is pleased to meeting you at booth 114 in Hall B5, to inform you in detail about the new products and the complete range of the LUMIMAX® product series.