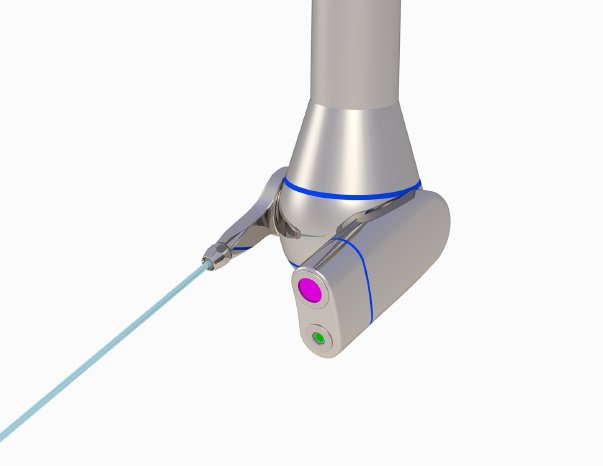

iiM AG developed the lighting for the smart tank cleaning system, the AJCsens adaptive jet cleaner, by working in close collaboration with the Fraunhofer Institute for Process Engineering and Packaging IVV, Hohe Tanne GmbH and Matrix Vision GmbH. The compact, movable jet cleaner featuring a Machine Vision system allows you to detect and clean internal geometries, including those that are difficult to access, such as guide plates, agitator blades or sensor connections, by using targeted methods. The degree of fouling in the tank is therefore recorded in real time. The means the successful cleaning outcome can be monitored and documented for the first time. Up to 60 % of resources (i.e. water, chemicals and time) are saved by adapting the cleaning program specific to the location and product in question.

Soiling is detected based on the fluorescence, which is excited by ultraviolet light from spot lighting. The light emitted by the contamination particles has lower energy than the light absorbed previously; a high luminous intensity is therefore required for a high-contrast camera image. This is achieved by using the latest generation High Power UV LEDs and integrated power electronics. A lens in front of the LED also focuses the light onto a defined area. This is because the lower the degree of soiling is, the brighter and more selective the lighting has to be.

However, the High Power means on the one hand that the fluorescence of the soiling is outshone by the light coming from the lighting itself. It is only by separating the excitation and transmission wavelengths using coordinated lens and illumination filters that the light coming from the lighting can be eliminated from the camera image. As a result, the fluorescent contamination particles appear brightly shining on a dark background in the camera image.

Where higher power levels are involved, heat management is becoming increasingly important to ensuring a stable process on the other hand. The lighting is integrated directly into the AJCsens casing, which requires a particularly compact design and makes heat convection more difficult. Thanks to the special housing and use of highly conductive materials, any heat generated is dissipated to the greatest possible extent via the integrated air cooling system.

Despite the cramped installation space, the entire power electronics are integrated into the lighting housing. This forms part of the smart process control system, meaning therefore that the lighting can be pulsed in sync with the camera. Regularly switching the lighting on and off instead of keeping it on at all times not only has a positive impact on heat management; it also helps to extend the system’s service life.

Taking into account the cramped installation space, difficult heat convention and stringent optical requirements for fluorescence use, we managed to come up with a reliable OEM solution by working together with our project partners. Thanks to our skill and expertise developed over many years in the Machine Vision market, iiM AG has managed to successfully come up with solutions for numerous customer applications. This has been achieved either by developing specific lighting concepts or adapting existing LUMIMAX® Lighting systems in line with hygienic design requirements for direct contact with food, for example.

At this year's VISION, as one of the trade fair highlights at the iiM AG booth, you can control a model of the AJCsens live and receive detailed advice on our customer-specific lighting solutions. iiM AG cordially invites you to visit its booth 10D51. Further information on the LUMIMAX® product range can also be found at: www.lumimax.com