1. Does it fit your requirements and workspace?

What working volume do you need for each batch and, having decided this, where can a unit of the right size be installed? Practicality this is simple, and it means you must have accurate dimensional drawings early in the process. Once there, can the necessary services be installed beforehand such as:

- Cooling water

- A low drain with heat-resistant pipework, that must also meet local municipal standards

- Electrical supply (both single and three phases are often needed)

- Oil-free, dry air and other gasses as needed (piped or bottled)

- Clean, dry steam (a steam generator may be integrated on units below 50L total volume)

- Process water (for filling and rinsing of larger vessels)

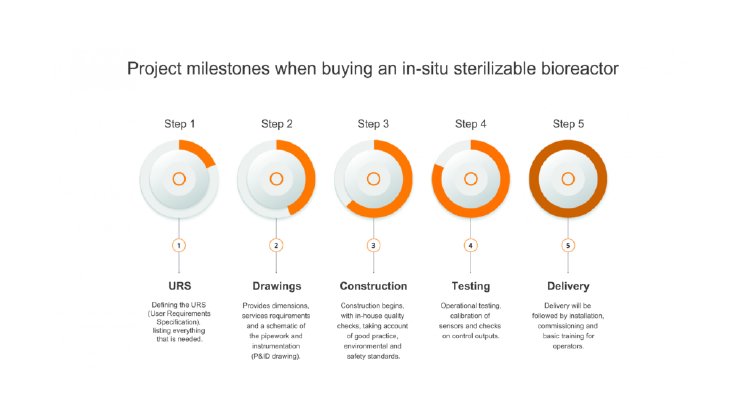

2. How is your order processed?

A User Requirement Specification (URS) should be prepared, listing everything needed. This is created after discussions with other stakeholders, site engineers and network specialists. The URS often makes the key element of an invitation to tender, which will be generated and managed by your Purchasing Department.

The URS will be analysed by specialists in different departments, to ensure each item is considered and a suitable response given in reply or as part of a formal quote. The responsibilities are divided as follows:

– Technical Support Construction (responsible for mechanical clarification and sequences)

– Technical Support Automation (responsible for the clarification of parameters, I/O list and electrical requirements)

– Quality Department (responsible for the required standards and quality documentation)

– Software (responsible for the requirements of control, recording, monitoring)

The reply to the URS will normally be a point–by–point confirmation. Any differences will be indicated, and alternatives suggested. At this stage, there may be questions and suggestions to consider. This will involve contact with the designers and other specialists to clarify these points.

Check the quotations carefully and make sure you compare “apples with apples”. Just because something can be fitted does not mean it will be fitted unless it is asked for. Furthermore, do not forget the peripheral items if you are setting up in a new location. Small items like reagent bottles will need sizing to the scale of the vessel and special fittings for transfer lines should be ordered in the right quantities. Even medium volume should be considered, especially if it is bought in ready for use.

3. Can the bioreactor be expanded over time?

A unit which has used up all its capacity for sensors and actuators at the outset may be difficult and expensive to upgrade. Therefore, a good indicator is if the controller has spare capacity to add analog signals or use a digital protocol such as Modbus. The vessel should be specified with spare ports (head plate and side ports) to allow for extra sensors if future expansion is likely, as these can be difficult to add later. Any costs associated with adding sensors to the local controller should be investigated when discussing specifications with suppliers.

4. How automated are the sterilization, cleaning and operating processes?

Automation of these processes is a critical factor and should especially be considered if trained operators are in short supply. These procedures should also be flagged and confirmed at the local Human Machine Interface (HMI) on the controller. Prepared phases and recipes are vital, with changes to standard options being recorded and stored between cycles. Steps initiated by the operator, such as seal testing and sample valve sterilization, should be timed and need no further action.

Furthermore, for cleaning in place procedures, the centrifugal pump and extra pipework needed can be mounted on the same frame as the bioreactor. This makes it compact, and as mobile as the bioreactor. Spray balls are fitted inside the bioreactor, through the top plate or side wall. It is usual to have two of these to ensure there are no “shadows” i.e. areas not cleaned by a single spray ball.

Lastly, safe operation for both operators and product are paramount. How the system behaves when, for example, steam pressure is lost should be examined. For operational steps, the ability to empty and fill reagent lines automatically can save time and effort. Local cascades and software-controlled workflows provided in the bioprocess software can reduce the need for operator interventions.

5. How easy is liquid-handling?

The traditional way of doing this is to use silicone septa in ports on the top plate and pierce them aseptically using a large needle. This still may be useful for some actions, such as addition of inoculum or small volumes of supplement. There are two further options to consider:

- A push valve removing the need for piercing a septum is good for reagents which can be autoclaved before use, along with the push valve. Multi port variants are also available.

- For feeds and liquids which must be used quickly, a sterile steam cross assembly can be used to connect a transfer line, sterilize the connection and then add the material.

6. Is the bioreactor simple to operate?

The operator interface, both local and remote, should be easily accessible for new users and familiar. A browser-based look and feel goes a long way to achieving this, compared to proprietary interfaces. Furthermore, user groups and password-protection are major security standards and usually required with validated processes. More complex items should be hidden from basic operators and easy to change for authorised users, except for service personnel who should have access to most sensitive items. With the bioprocess software in mind, this should be capable of qualification and supply full user management and an audit trail. Creation of recipes, workflows and soft sensors are all “must haves” for a modern package. The ability of users to interact with the software remotely guarantying strong security makes day-to-day supervision of multiple processes that much simpler.

7. How accessible is the vessel?

An in-situ sterilizable bioreactor relies on many more values and other components not needed on bench-scale units. If these are hidden behind housings this can impede maintenance and repairs. Small systems only need a support column on which to mount the vessel and controller. Valves and heating elements etc. can be mounted behind the cabinet but with free access. The single support column is advantageous because the vessel only needs a single load cell for weight measurement. Furthermore, these units can use a small crane to lift the vessel top plate, which can be mounted onto the same frame without inpinging upon most ceilings. Once the crane has lifted the top plate and drive shaft/baffles clear of the vessel, it should have a swivel action to move them out of the way.

Larger units have an “open frame” design as standard. This provides full access to valves, pumps, heat exchangers gas pipework and the motor. This is a real benefit for complex designs with many sterile crosses and extra pipework. These systems have an option of a swivel top plate, which removes the need for a crane. The mechanism is built into the lid and allows it to raise slightly and be moved out of the way, Again, space must be available for this to happen. In this case the baffles do not move with the top plate but should be removable for cleaning the inside of the vessel

8. Is the motor powerful enough and where is it located?

A larger vessel means larger impellors and the drive motor must be powerful enough to move them through the medium at a reasonable speed. The good news is that impellor tip speed can be used as a scale up criterion, and the stirrer speed can be lower as the impellor diameter is larger. Smaller vessels will have a top-mounted motor for both microbial and cell systems. They rely on a simple mechanical seal or magnetic coupling for low-speed cell culture motors. It is easy enough to engineer a frame-mounted holder for the motor, which makes handling easier.

For larger vessels, even a microbial motor can be bottom mounted. When this is possible, other refinements become possible:

- A water-cooled motor for operation at higher speeds as the cooling is far more efficient than with air.

- Where vertical space is tight, a powerful magnetic drive can be used in place of a single or double mechanical seal.

Smaller vessels can utilize electrical heating for operational temperature control and even for sterilization. The options are to use steam just for sterilisation or for both. Using electrical heating for both is possible but soon becomes inefficient for vessels sizes of 20L and beyond. The time needed to heat the medium (which is heated under pressure to generate the steam) can be several hours. If house steam is unavailable, using a steam generator mounted on the vessel frame will be more efficient. In this case, using electrical heating for operation makes the most sense, so the steam generator is not in permanent use. Cooling often uses direct injection of cold water into the vessel jacket. It is also important to note that steam is still required to sterilize sampling valves, and if the end user intends to do this frequently, it may be best to simply use steam vessel heating as well.

For larger in-situ sterilizable bioreactors, steam is necessary and can be injected into the vessel or passed through a heat exchanger. This transfers the heat to a circulating liquid which passes through the vessel jacket. A second heat exchanger can be used for cooling. For high density culture, the exchangers must be adequate to deal with the excess heat generated by the culture.

10. How is validation and qualification ensured?

If working under GMP conditions, validation and qualification is necessary. Therefore, strict as well as neat documentation from the beginning of deciding for an in-situ sterilizable bioreactor until the installation is especially important. It is important for all parties to discuss the scope of the project and document requirements at the outset. In the following key document requirements are mentioned:

- Design Qualification (DQ)

- Factory Acceptance Testing (FAT)

- Installation Qualification (IQ)

- Site Acceptance Testing (SAT)

- Operational Qualification (OQ)