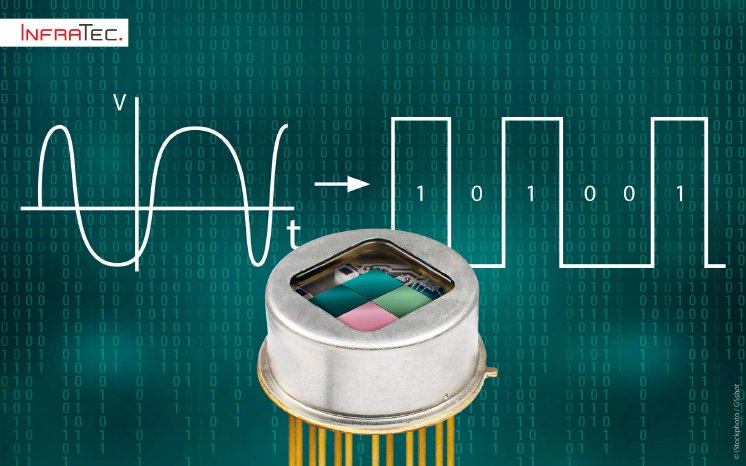

An overview of the digital detector

Like all detectors from InfraTec, the digital detector is based on lithium tantalate (LiTaO3) and is used in the field of gas analysis and flame detection. It enables complete flexibility in the configuration of the detector parameters and therefore variable signal processing. In addition, it offers improved electromagnetic compatibility (EMC), as the entire signal conversion of the detector is spatially concentrated and shielded. The digital detector offers a wide range of further benefits.

It is equipped with a clock input (pin) to synchronise the radiator and the detector clock. This means that a time signal with a highly precise sampling rate can be generated. An additional, special feature is the „fast recovery after saturation “. This function detects the override due to a defective operating status and automatically resets the analog input stage.

The digital detector converts the analog signal with a 16-Bit resolution directly into a digital signal. The analog signals can be multi-stage adjustably filtered and strengthened. The complete signal processing is performed via an ASIC (application-specific integrated circuit) with integrated A/D-converter, whereby the analog input stage acts like a transimpedance amplifier. Users receive a digital measurement signal, which can be read out via a standard communication interface and processed immediately.

Two completely different detectors

The digital detector will expand the portfolio comprising analog detectors in the future. Which of the two variants is used, depends mainly on the complexity of the measuring tasks. Both detectors have their strengths and offer different benefits.