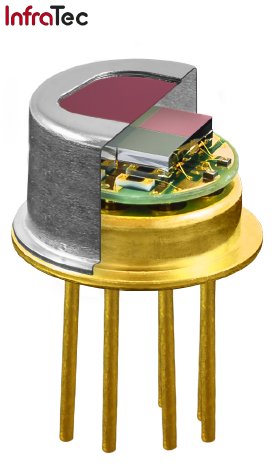

A mere glance at its appearance gives clues about this sensor's first unique feature. In the cap where conventional multi channel detectors have sensitive narrow bandpass channel filters with special adhesive mounted, a central window has been added in the detector cap instead. This significantly more robust broadband filter, e. g. made of sapphire, offers substantially better protection against penetrating moisture. It can also be soldered to the housing to create a complete hermetic seal.

The channel filters are now placed inside the detector instead. There, they are shielded from mechanical and physical stress, as well as from other strains from harsh environments – and they are also located even closer to the pyroelectric elements. The reduction of this distance and the central window integrated into the detector cap are two of the factors that ensure that the field of view (FOV) is now significantly wider. At the same time, all elements are placed closer together inside the detector. This allows more radiation to reach the pyroelectric element and therefore a higher signal. In addition, since the optical correspondence of the individual channels remains consistently low, the LRM-254 proves to be extremely powerful.

The new detector is an example of an innovative product line, and one that provides users with additional possibilities for the use of sensors. The compact, miniaturized construction allows for more analysis channels with unchanged detector size. Or, the same number of channels can be integrated into significantly smaller packages.

This space saving and robust design will especially appeal to users who want to integrate sensors in mobile devices. In the fields of gas and flame sensor technology, this increasingly compact periphery plays a crucial role. With the LRM-254, which even can be thermally compensated due to its minimized stack design, you now have important new flexibility thanks to the latest developments by InfraTec.