The future of car light lies in dazzle-free main beams in HD quality and in a tight interaction between vehicle and innumerable sensors. The board computer receives detailed information about the environment from sensors that calculate in real time the brightness values for each of over two million pixels. Further functions such as symbol and video projection onto the road add to the complexity of the lighting devices. Traditional methods of measuring light distribution with a far-field goniophotometer and illuminance meter have become inefficient and inadequate, as they are not fast enough for measuring every possible lighting scenario in an R&D environment.

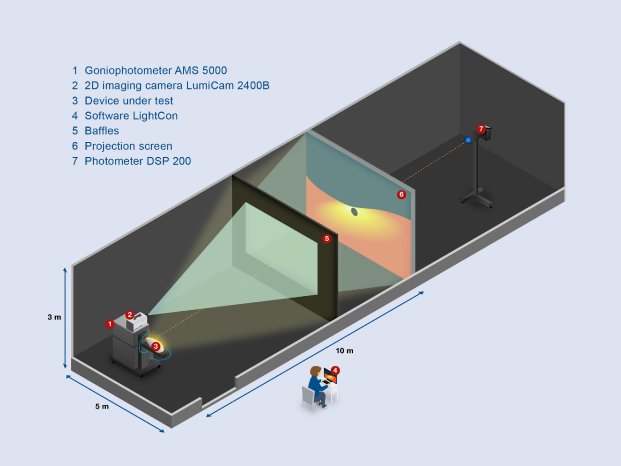

Instrument Systems offers with the Optronik Line AMS Screen Imaging System a highly efficient solution for testing all kinds and lighting scenarios of advanced headlamps, e.g. HD / ADB / matrix / pixel headlamps. The newly developed system represents a fast method of combining camera-based luminance measurements on a projection screen (screen photometry) with goniometric far-field measurements in the light lab. The objective is to save time while maintaining a high level of accuracy. The system setup includes a classic AMS 3000 or 5000 far-field goniophotometer with a DSP 200 fast illuminance meter positioned beyond the photometric limiting distance. The camera used for screen photometry is the recent LumiCam 2400B camera with five mega pixels, allowing an excellent resolution for the measurement of all common, but also state-of-the-art HD headlamps. For quick and easy operation, the test results of both measurements can be simultaneously analyzed with the LightCon software.

The AMS screen imaging system must be set up in a light channel of at least 25 m length. In order to record the complete light distribution of the headlamp, the goniometer rotates the sample while the camera is taking a series of images that are later stitched in one image or test report. The AMS screen imaging system is supported by an extension module of the advanced LightCon software that allows compliance check according to ECE / SAE / ICAO / FAA regulations as well as extensive graphical visualization for isocandela diagrams.