Instrument Systems has developed a practicable concept for the laser safety assessment of VCSELs based on the international laser safety standard. With absolutely calibrated and modular test systems, such as the pulsed VCSEL tester PVT 100/110 and camera-based VTC 2400, the complete characterization of pulsed VCSEL arrays is possible. Since VCSEL arrays are experiencing a drastic growth in 3D sensor applications, e.g. face ID, automotive LiDAR and human-machine-interfaces (AR/VR), proof of eye safety is becoming increasingly important.

Surface emitting lasers (VCSEL) have been in use in industrial applications for over three decades. Lately, 3D sensor applications, e.g. face ID, automotive LiDAR and human-machine-interfaces (AR/VR) have been enjoying increasing popularity. Due to their unique properties and an extremely high degree of efficiency, a narrow spectrum, reliable radiation properties and low production costs VCSEL arrays are perfectly suited to 3D sensor applications. However, like all lasers, VCSELs can cause serious damage to the human eye and skin. The manufacturers of final products containing VCSELs are thus obliged to carry out a laser safety assessment according to the international standard IEC60825-1 or equivalent national safety regulations.

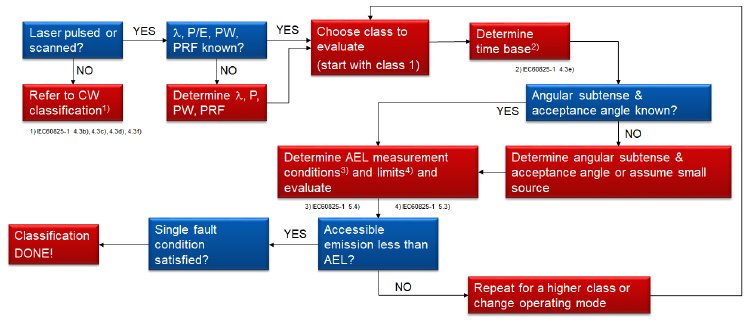

Instrument Systems has developed a practicable concept for laser safe viewing of VCSELs that conforms to the international laser safety standard. It is based on a laser class assessment chart and modular test system that is absolutely calibrated, and delivered with a test certificate for the error budget. The two main modules of the test system are the pulsed VCSEL tester PVT 100/110 and camera-based VTC 2400. The PVT 100/110 is a custom solution for the control and measurement of nanosecond pulses as used for LiDAR or time-of-flight applications. Typical measurement parameters are wavelength, repeat frequency, pulse width, pulse energy or pulse sequence. The PVT 100/110 offers a high spectral resolution (≥ 0.12 nm), extremely short pulse sequences up to 1 ns and 50A current as well as test pulse sequences with a repeat rate of more than 100 MHz. The camera-based VTC 2400 enables far-field analysis of the spatial radiation properties of VCSEL arrays. Typical measurement parameters are average power, beam profile, highest intensity spot and angle of divergence (for the spot area).

The laser class assessment chart developed by Instrument Systems complies with the guidelines of international laser safety standard IEC60825-1 and offers a practicable concept for determining the laser safety of pulsed VCSELs with VCSEL test systems PVT 100/110 and VTC 2400. All critical parameters are identified in a few steps, e.g. beam divergence, pulse length or duty cycle. The highly precise, calibrated test systems have a minimum absolute error budget. This enables the full performance efficiency of the VCSELs to be exploited while assuring safe operation.

A complete explanation of laser class assessment can be seen in our video at: https://www.instrumentsystems.com/en/news-portal/eye-safety

Visit us at Productronica from 16–19 November 2021 at Stand B2.315.