Irlbacher's intuitively operable touch surfaces, which do not require a touch screen, are becoming increasingly popular. This is because finger guides, slider or encoder-like operating elements ground into the cover glass make reading the operating instructions a time-wasting issue. In addition, all production takes place in Europe; dependence on special displays with their sometimes awfully long supply chains is completely avoided.

Irlbacher applies logos, inscriptions and other colour layers to the glass using inorganic and, above all, environmentally friendly ceramic screen printing. Using this high-precision technology, which is applied in a clean-room environment, the company complements design-oriented colour printing with functionalised printing of pcb tracks and electronic circuits. Thanks to an optical barrier layer, the electronic layout is not visible from the front. In the subsequent tempering process, simple float glass is transformed into high-quality toughened safety glass; the individual colour and functional layers enamel to form a materially bonded, monolithic composite.

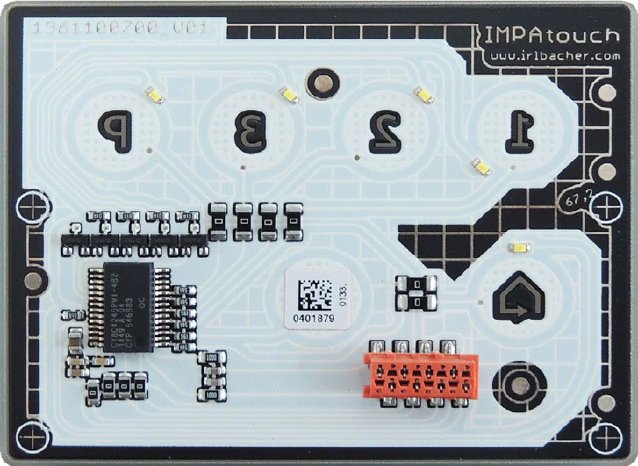

With this technology, called IMPAeGlass, structure below 80 µm can be realised in series production. Thanks to these fine-pitch conductors, microcontrollers of the QFN (or MLF), SOP or SSOP types can be assembled directly and conventionally on glass. The advantage: the electronics printed on glass enable very slim mounting heights. Depending on the capacitors and connectors, values of less than 10 mm can be achieved - including glass and touch sensors.

The touch sensors are read-out in real time by powerful 32-bit microcontrollers. Irlbacher's firmware can easily distinguish between hands, even those with gloves, as well as water drops or other artefacts.

The enormous computing power of the modern SoCs used can take on further tasks, such as controlling electrical appliances, medical devices, or intelligent measuring instruments. Together with the customers, the complete application is thus embedded in the touch controller, which completely replaces dedicated control boards etc. and thus reduces costs and drastically shortens development times.

With IMPAeGlass, the entire electronics for HMI, display, device control, coupling of sensors or WLAN connectivity etc. are located directly on the glass. To ensure that the elegant glass front can be optimally integrated into the device design, Irlbacher also develops the customised cover frames, brackets, or mounting solutions.