The alliance benefits customers, who receive high-performance solutions for smart factory automation as well as comprehensive support from consulting to commissioning and service – all directly from a single source. As such, customers can rely on the expertise and experience of over 1,200 employees, ensuring customer proximity and personalized services as well as fast response times at 18 sites around the world. By combining development, production, and direct sales, the joint businesses are able to address customer needs in a targeted manner.

For customers to benefit to the greatest possible degree from the experience of the three market leaders in their respective sectors, ISRA VISION, Perceptron, and QUISS have established joint competence centers for the four key areas of surface inspection, quality vision, industrial metrology, and robot vision. This includes defining comprehensive solutions and products for the future that will support customers in setting new quality standards in their respective industries.

For surface inspection, ISRA VISION’s portfolio includes solutions for fully automated surface inspection at highest speeds, enabling full automation and detection accuracy throughout the entire production line in key application areas - such as the automotive industry, electronics, or white goods manufacturing. This enables customers to achieve extraordinarily high and reliable product quality, as well as efficient and profitable production processes.

In the area of quality control, the company has enhanced its products portfolio with technologies from QUISS. The result are state-of-the-art solutions ensuring compliance with specified quality standards, 100% quality inspection, and defect-free processes. These systems collect data that can

then be used to further improve process quality, efficiency, and productivity. Perceptron provides solutions and expertise for automated 3D measurement technology, generating real-time information on components and processes and ensuring first-class quality while reducing waste through the fully automatic inspection of gap widths and flushness on any material.

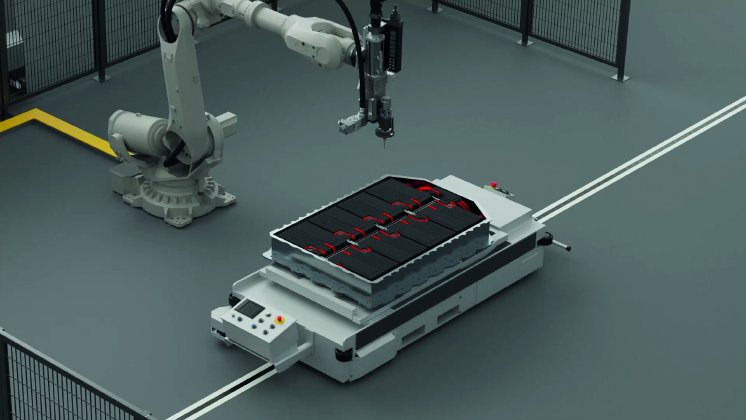

The group of companies has another strength to offer: solutions for robot vision. ISRA VISION and Perceptron leverage their synergies to develop integrated systems for contactless identification and position detection and the optimal joining of components. These systems have proven their value in numerous industries thanks to their robust and highly accurate processes, while at the same time ensuring high processing speeds as well as maximum machine and plant availability.

Tomas Lundin, Managing Director of ISRA VISION, states: “The alliance between ISRA VISION, Perceptron, and QUISS is a tremendous success for us - and our customers. The products complement each other perfectly, enabling us to offer solutions for industrial image processing for surface inspection, quality assurance, metrology, machine vision and 3D robotics – all from a single source. Our portfolio for smart factory automation is taking Industry 4.0 to the next level, integrating even smarter technologies and 3D products for in-line, at-line, and off-line applications. Our experts support our customers with services ranging from consulting to commissioning and beyond – ensuring global customer proximity through direct sales channels.

In the future, the global market leader for industrial image processing will collaborate closely with customers and OEMs to develop further innovative technologies, solutions, and products. This approach will enable ISRA VISION, Perceptron, and QUISS to expand their global market coverage and support their customers in continuously improving quality of production and profitability.