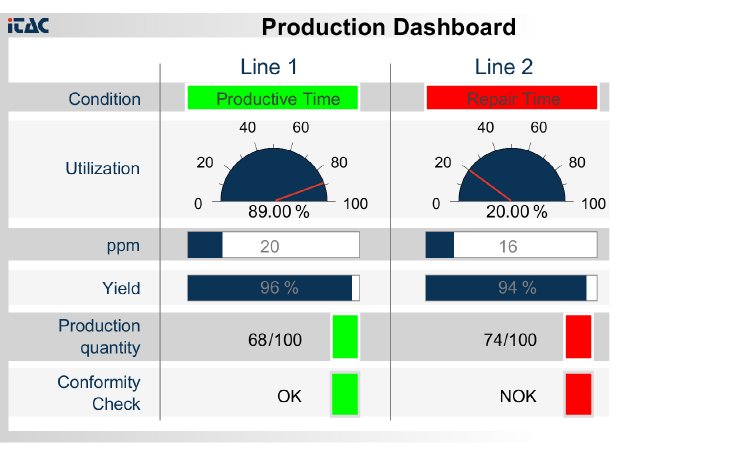

The sphinx open online visualization software has been connected to the iTAC.MES.Suite manufacturing execution system to reflect the principle of “live production process control”. It provides the factory with a dashboard for the visualization and online monitoring of performance and quality-relevant KPIs. The production data in the iTAC.MES.Suite is transferred to sphinx open online without any programming requirements whatsoever. A graphic editor is used to simply create special dashboards for the clear visualization of the relevant KPIs.

This Enterprise Manufacturing Intelligence (EMI) application for the online visualization of KPIs such as OEE, FPY, FRY etc. is already used by companies around the world such as HELLA KGaA Hueck & Co., a German automotive supplier with international operations.

Up-to-date with Java-EE and cloud capability

iTAC and in-GmbH have both focused on Industry 4.0 requirements. Both systems are based on the Java EE standard to provide flexibility and scalability in the implementation of global projects. Additional cloud capability means that the data can be retrieved on mobile devices in real time from anywhere in the world. The open architecture of sphinx open online enables the integration of other services and, for example, mobile clients with simplified dashboards.

“In collaboration with in-GmbH we provide an intelligent tool that satisfies key smart factory requirements – and unites globalization, flexibility, resource and cost efficiency, as well as operational reliability,” explained Andreas Zerfas, Director Product Management at iTAC Software AG.