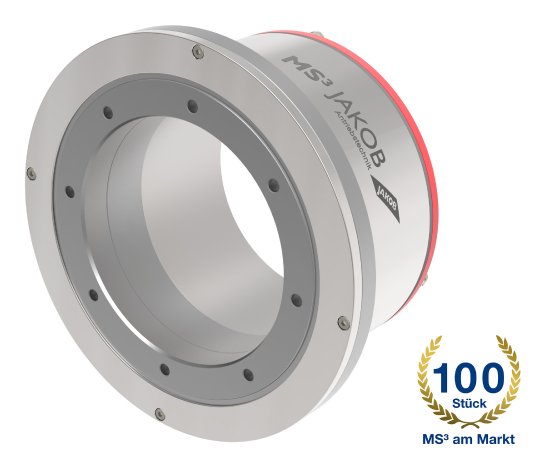

The motor spindle protection system MS³ interrupts the flux of force at the interface between the spindle frame and the motor spindle by means of 3D deflection, in the event of collision-induced overload. As a result, the shock-sensitive components of the motor spindle are effectively protected from the high force peaks in case of a collision or an overload situation.

Characteristics:

• No external energy supply necessary

• Faster than purely electronic process monitoring systems

• High lateral adhesion and system stiffness for safe operation

• Absorption of the kinetic impact energy by dampers

• Integrated interrogation of the deflection state for emergency stop

• Self-resetting of the motor spindle with high precision

• Increased machine availability

• Adaptable to all common motor spindle geometries

• Maintenance free