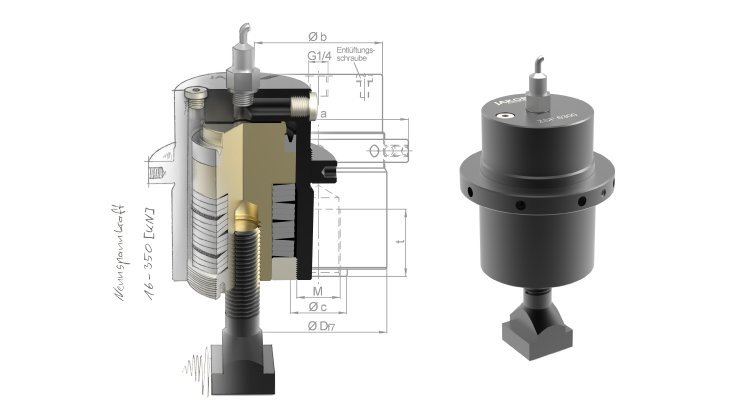

The spring clamping systems work through a combination of mechanical and hydraulic principles. The clamping force is generated mechanically by preloaded disc springs, while hydraulics are only required to loosen the elements to release the tie rod or pressure bolt. This means that the clamping force remains constantly high regardless of oil pressure or leakage losses, which increases operational safety.

The pressure or pull piston is influenced alternately by the disc spring package or the hydraulic pressure. As the oil pressure increases, the spring package compresses and increases the spring force until the desired clamping force is achieved. To release the push or pull piston, a higher hydraulic pressure is required, which is proportional to the release stroke.

Another advantage is that the setting pressure is only required during initial assembly for fine adjustment of the force. In the normal operating cycle, the cylinders are operated either without pressure or with a release pressure. For spring clamping cylinders, a mandrel or tie rod is screwed into the threaded hole of the tension piston and secured (available in one piece or with a special thread upon request). All that is required for operation is a hydraulic unit, which should be equipped with a pressure gauge, a pressure relief valve, a switching solenoid valve and a pressure switching device.

The hydromechanical spring clamping systems offer numerous advantages, including short operating times of the hydraulic unit, low acquisition costs, increased operational safety, versatile areas of application and simple operation.